How Much Should You Charge for PAT Testing? A Practical Guide for Sparkies and Safety Managers

"How much should I charge for PAT testing?". This question appears constantly in electrician forums, procurement groups, and safety manager discussions. The answers range from £0.70 per item to £5.00+ per item, with some suggesting day rates of £200-£400 and others recommending minimum call-outs of £60-£100.

- Technical review: Thomas Jevons (Head of Training, 20+ years)

- Employability review: Joshua Jarvis (Placement Manager)

- Editorial review: Jessica Gilbert (Marketing Editorial Team)

- Last reviewed:

- Changes: Updated for 2026 market rates, EAWR compliance guidance, and regional pricing variations

“How much should I charge for PAT testing?”

This question appears constantly in electrician forums, procurement groups, and safety manager discussions. The answers range from £0.70 per item to £5.00+ per item, with some suggesting day rates of £200-£400 and others recommending minimum call-outs of £60-£100.

The confusion stems from fundamental misunderstandings about what PAT testing actually involves, what drives costs, and what constitutes compliant work under the Electricity at Work Regulations 1989.

Here’s the 2026 reality: Per-item pricing is marketing shorthand that obscures the true cost structure. A proper PAT inspection takes 5-10 minutes per item when you include visual checks (where 80-90% of faults are actually found), electrical testing, labelling, and documentation. Anyone claiming they test 50 items per hour is almost certainly skipping the visual inspection, cutting corners on reporting, or both.

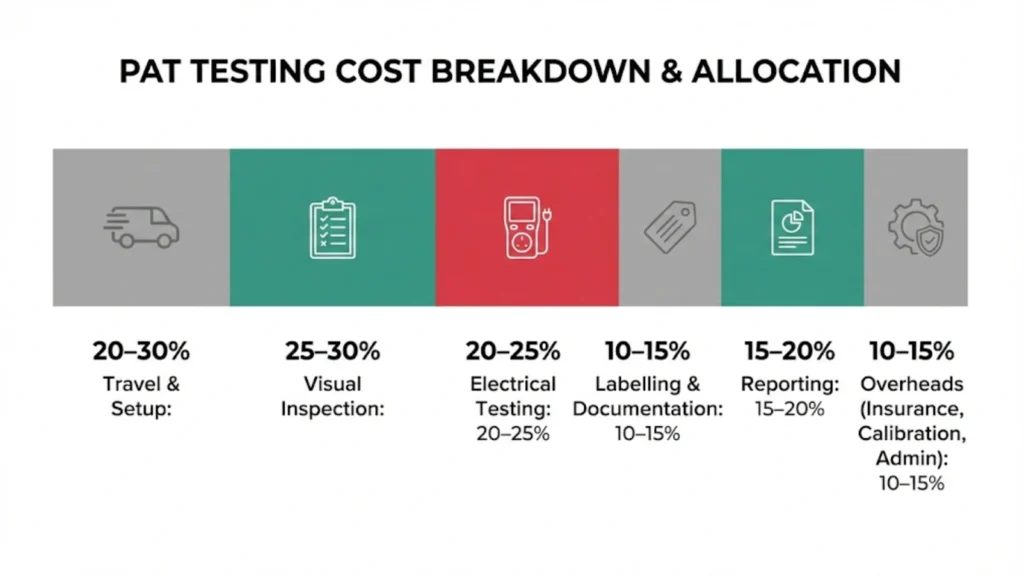

Underpricing below £1.50 per item for small batches is economically impossible for legitimate, compliant work once you account for travel time (20-30% of total cost), setup and risk assessment, comprehensive reporting (1-2 hours post-job), equipment calibration (£100-£200 annually), insurance premiums (£500+ for adequate public liability), and business overheads.

This creates two distinct problems:

For electricians: Competing with £0.70 national providers is a race to the bottom that destroys sustainable businesses and forces corner-cutting that exposes you to liability claims.

For safety managers: Accepting the cheapest quote often means inadequate testing, incomplete records, and legal exposure when incidents occur—the duty-holder’s EAWR 1989 responsibility doesn’t disappear because you hired cheap contractors.

This guide explains how PAT testing is actually priced, what drives real costs, how electricians should structure quotes to remain profitable while maintaining quality, what safety managers should look for beyond lowest price, and why regional variations (London £2.50-£5.00 versus Midlands £1.50-£2.50) reflect genuine operating cost differences rather than arbitrary pricing.

Why "Per Item" Pricing Is Fundamentally Misleading

The £1.50 per item quote sounds simple and comparable. But it hides the actual work structure.

What a proper PAT inspection actually involves:

Travel and site setup (20-30% of total time):

Driving to site (fuel costs, vehicle wear, time) Parking, site access protocols, sign-in procedures Initial risk assessment and discussion with duty-holder Setting up testing equipment and documentation systems

For a small office 30 minutes away, this represents 1-1.5 hours before you touch a single appliance. That fixed cost exists whether you’re testing 10 items or 100 items.

Visual inspection per item (3-5 minutes):

Check cable and plug for damage, overheating, or incorrect repairs Verify fuse rating matches appliance requirements Inspect strain relief and cable entry points Look for signs of liquid ingress or mechanical damage Check appliance casing for cracks or exposed internal parts

The HSE and IET Code of Practice both emphasize that visual inspection is where the majority of faults are detected. Electrical testing primarily confirms what the visual check suggests. Anyone doing “PAT testing” in under 2 minutes per item is skipping this critical stage.

Electrical testing per item (2-4 minutes):

Plug appliance into calibrated PAT tester Conduct earth continuity test (Class I equipment) Perform insulation resistance test Check polarity and earth leakage Record all readings for compliance documentation

Labelling and documentation (1-2 minutes per item):

Apply pass/fail label with date and next test due Record asset details (serial number, location, user) Enter test results into asset register Photograph failed items for client records

Post-job reporting (1-2 hours regardless of item count):

Generate comprehensive asset register Create pass/fail summary with photographs Provide retest recommendations based on risk assessment Format report for client recordkeeping (EAWR compliance evidence)

The mathematics of per-item pricing:

Small office scenario: 30 items tested

Travel/setup: 1.5 hours Testing time: 30 items × 8 minutes average = 4 hours Reporting: 1.5 hours Total time: 7 hours

At £1.50 per item: £45 revenue ÷ 7 hours = £6.43/hour (below minimum wage) At £2.50 per item: £75 revenue ÷ 7 hours = £10.71/hour (still below sustainable rate)

This excludes fuel, calibration costs, insurance, equipment depreciation, and any business overhead. The mathematics only work at scale (100+ items where travel percentage drops) or with higher per-item rates.

Why “per item” persists despite being misleading:

Clients understand it easily and can compare quotes numerically Marketing simplicity trumps cost accuracy National providers achieve scale that sole traders cannot match The lowest number wins procurement processes that prioritize price over compliance quality

But for sole traders and small electrical contractors, per-item pricing below £2.00-£2.50 (without substantial minimum call-out) represents unsustainable economics that inevitably leads to corner-cutting.

The Real Cost Drivers Electricians Must Account For

Sustainable PAT pricing requires covering actual costs, not just competing on headline numbers.

Fixed costs per job (regardless of item count):

Travel and setup: 1-2 hours minimum. At £30-£40/hour target rate for electrician time, that’s £30-£80 before touching equipment. This is why minimum call-out fees of £60-£100 are essential for small jobs.

Insurance premiums: Public liability insurance (£2-£5 million cover) costs £400-£800 annually for sole traders. Professional indemnity adds another £200-£400. For 100 jobs per year, that’s £6-£12 per job in insurance costs alone.

Equipment calibration: PAT testers require annual calibration to ensure accurate readings. Calibration costs £100-£200 per instrument. Testing incorrect readings could pass dangerous equipment—your liability exposure is enormous.

Business overheads: Vehicle costs (fuel, maintenance, insurance), accounting software for record-keeping, mobile phone, liability for storing client data under GDPR, training updates (City & Guilds 2377 refreshers, regulation changes).

Variable costs per item:

Appliance complexity: Class I equipment (earthed metal appliances) requires additional earth continuity testing versus Class II (double-insulated plastic-bodied equipment). 110V industrial equipment, three-phase appliances, and specialist IT equipment all take longer to test correctly.

Environment accessibility: Appliances in clean office environments are quick to access. Equipment in workshops (covered in dust, oil, or debris), kitchens (behind counters, grease buildup), or industrial settings (height access required, contaminated) adds 30-50% to testing time.

Failed item management: What happens when equipment fails? Repairing on-site (replacing fuses, fitting new plugs) adds time but provides value to client. Simply labelling as “failed” leaves client with non-functional equipment and potential additional call-out costs.

Reporting depth: Basic pass/fail list with sticker dates takes minimal time. Comprehensive asset register with serial numbers, locations, user assignments, fault descriptions, and photographic evidence of failures takes 1-2 hours for 50-100 items.

Risk-based frequency recommendations: EAWR 1989 doesn’t mandate annual testing—it requires risk-based maintenance. Providing clients with proper risk assessment and frequency recommendations (kettles 6-12 months, monitors 2-4 years) adds value but requires competence and documentation time.

Hidden costs of underpricing:

Reputation damage: When your £50 PAT test skips visual inspections and a client’s kettle with frayed cable causes a fire, your insurance may not cover inadequate workmanship. Your reputation suffers, and you potentially face HSE investigation.

Business burnout: Working at £10-£15/hour (after costs) isn’t sustainable. You either quit electrical work, cut corners to speed up (increasing liability), or raise prices and lose clients who’ve been conditioned to expect unrealistic rates.

Market distortion: Ultra-low pricing trains clients to expect £0.80 per item as “normal,” making it harder for legitimate contractors to compete on quality and compliance rather than price.

The reality: Sustainable PAT pricing for sole traders requires minimum £60-£100 call-out for small jobs (under 30 items), plus £2.00-£3.00 per item for standard office/retail environments, adjusted upward for industrial complexity or difficult access.

How Electricians Should Structure PAT Pricing

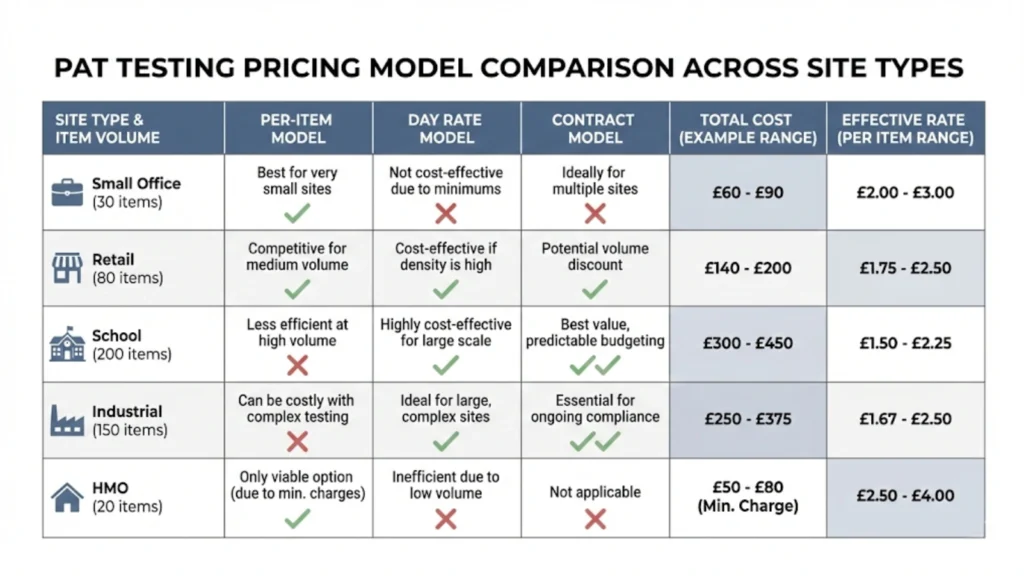

Three primary pricing models exist, each suited to different scenarios.

Model 1: Minimum call-out + per-item rate

Structure: £60-£100 minimum fee + £2.00-£3.00 per item

Best for: Small to medium jobs (10-100 items), sole traders, diverse client base

Why it works: Minimum fee covers travel/setup/reporting fixed costs. Per-item rate covers variable testing time. Clear, understandable for clients.

Example: Small office (30 items) Minimum fee: £75 Per-item: 30 × £2.50 = £75 Total: £150 (5-6 hours work = £25-£30/hour effective rate)

Model 2: Day rate or half-day rate

Structure: £250-£400 full day (8 hours), £150-£250 half-day (4 hours)

Best for: Large sites (100+ items), industrial environments, complex access, ongoing contracts

Why it works: Removes incentive to rush. Allows time for thorough visual inspections, dealing with failed items, comprehensive reporting. Client knows exact cost regardless of final item count.

Example: Industrial workshop (150 items, challenging environment) Day rate: £350 Actual items tested: 120-150 depending on complexity Client budgets accurately, electrician works properly without time pressure

Model 3: Risk-based contract pricing

Structure: Site assessment → annual contract covering all testing, reporting, and minor repairs

Best for: Large facilities, multi-site organizations, ongoing relationships

Why it works: Predictable costs for client, guaranteed work for contractor, allows proper risk assessment and frequency planning rather than blanket annual testing.

Example: Retail chain (5 sites, 500 items total) Annual contract: £1,800 (includes 2 visits per year, all reporting, minor repairs) Effective rate: £3.60 per item per year, but distributed efficiently

Regional pricing adjustments:

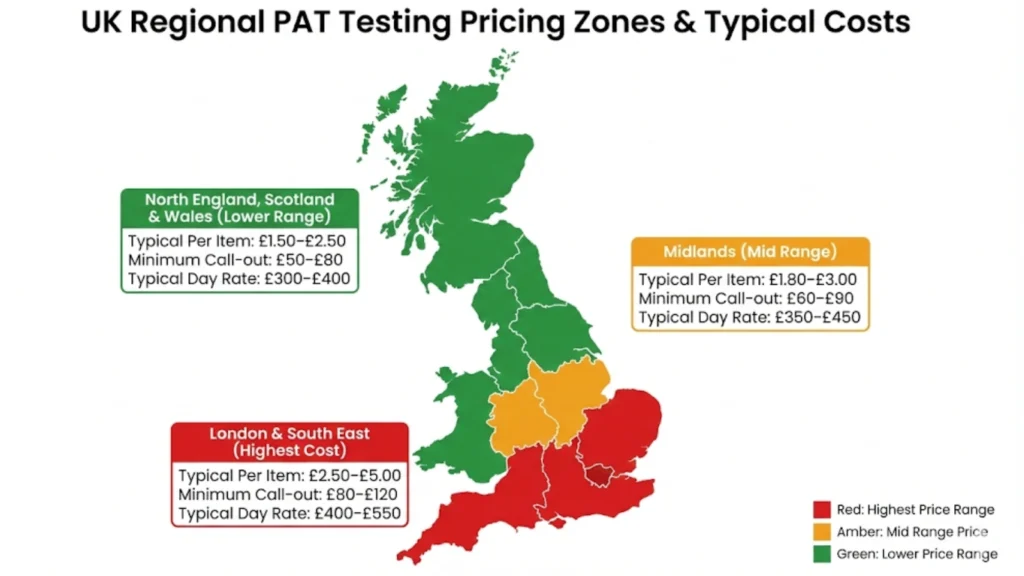

INTERNAL LINK #1: The regional wage differences affect pricing significantly, with London and South East commanding 20-35% premiums over Midlands and Northern regions due to higher operating costs, transport expenses, and cost-of-living differences.

London/South East: Minimum call-out £90-£120, per-item £2.50-£5.00, day rate £350-£500

Midlands (Birmingham/West Midlands): Minimum call-out £60-£90, per-item £1.80-£3.00, day rate £250-£350

North/Scotland/Wales: Minimum call-out £50-£80, per-item £1.50-£2.50, day rate £200-£300

These aren’t arbitrary. They reflect actual wage costs, fuel prices, insurance premiums, and business overhead variations across UK regions. Pricing below your regional baseline means working at unsustainable rates.

Sector-specific adjustments:

Domestic/small commercial: Standard rates (simplest environment)

Schools/care homes: Add 10-15% for DBS check requirements, out-of-hours access, vulnerable user considerations

Industrial/workshop: Add 20-30% for 110V equipment, harsh environments, specialist testing requirements, higher risk

Construction sites: Add 25-40% for temporary installations, site access logistics, coordination with other trades

When to quote lower:

High-volume regular contracts: If you’re testing 500+ items monthly for same client, volume discount of 20-30% is sustainable because travel percentage drops dramatically.

Bundled services: Combining PAT with EICR (fixed wire testing) or other electrical work reduces effective per-item cost because you’re already on-site.

Training opportunities: Apprentices or newly qualified electricians building PAT competence might accept slightly lower rates for experience, but never below cost recovery.

When to quote higher:

Out-of-hours work: Evening/weekend testing for businesses that can’t have equipment unplugged during operating hours—add 30-50%.

Specialist equipment: Medical devices, data center equipment, industrial control systems requiring advanced competence—add 50-100%.

Urgent turnaround: Client needs certification within 24-48 hours instead of normal 7-day turnaround—add 25-40%.

Failed item liability: If you’re providing “pass” certification rather than just inspection reporting, you’re assuming greater liability—price accordingly.

Typical UK Price Ranges by Environment (2026)

These are market-observed ranges, not recommendations. Actual pricing depends on regional costs, business model, and service quality.

Small office (10-50 items):

Typical quote: £65-£150 flat fee or £1.80-£2.50 per item + £60 minimum

Key assumptions: Low-risk office equipment (computers, monitors, printers), easy access, standard working hours, basic reporting

Why this range: Small item count means travel/setup/reporting represent 40-50% of total cost. Per-item pricing without minimum call-out is economically impossible.

Red flags: Quotes under £50 total for 30 items (£1.67 per item) suggest inadequate work.

Retail unit (50-100 items):

Typical quote: £100-£300 or £1.50-£2.80 per item

Key assumptions: Mixed equipment (tills, lighting, kitchen appliances), some behind-counter access challenges, daytime working, standard reporting

Why this range: Volume begins to reduce travel percentage. But retail environments often have equipment in awkward locations (behind displays, in stockrooms) that increase per-item time.

Red flags: Quotes suggesting 100 items in 2 hours (claimed £150 cost at £1.50/item) physically impossible for compliant testing.

School or care home (100-300 items):

Typical quote: £200-£600 or £1.20-£2.00 per item

Key assumptions: High item count, vulnerable users requiring thorough testing, DBS clearance required, often out-of-hours access (evenings/weekends), detailed reporting expectations

Why this range: Volume reduces per-item cost, but DBS requirements, scheduling complexity, and liability considerations (vulnerable users) maintain price floor.

Red flags: Quotes lacking DBS certification for environments with children or vulnerable adults.

Industrial site or workshop (100-500 items):

Typical quote: £300-£1,500+ or £2.50-£5.00 per item, often quoted as day rate £300-£450

Key assumptions: 110V equipment common, harsh environments (dust, oil, moisture), three-phase appliances, higher risk usage patterns, specialist equipment, comprehensive reporting

Why this range: Testing 110V equipment properly requires different procedures. Industrial environments mean equipment is dirty, damaged more frequently, and used in ways that accelerate faults. Liability higher due to industrial accident potential.

Red flags: Quotes treating industrial environments same as office rates suggest lack of understanding of actual risks and testing requirements.

Landlord HMO (10-30 items per property):

Typical quote: £40-£110 per property or £2.50-£4.00 per item + £50 minimum

Key assumptions: Domestic-level equipment (kettles, vacuum cleaners, lamps), single location, standard testing, basic reporting for tenant records

Why this range: Small item counts mean minimum call-out essential. Often bundled with EICR (electrical installation condition report) for better value.

Red flags: Quotes lacking EICR option or suggesting PAT alone meets legal obligations (landlords need both).

Large facility or multi-site contract:

Typical quote: £800-£5,000+ annually or £250-£400 per visit

Key assumptions: 500-2,000 items total, multiple visits per year, ongoing relationship, comprehensive asset management, risk-based frequency planning, minor repairs included

Why this range: Contract pricing allows amortizing setup costs across multiple visits. Predictable costs for client, guaranteed work for contractor.

Red flags: Contracts lacking risk assessment or applying blanket annual frequency to all equipment regardless of actual usage patterns.

What Safety Managers Should Look For (Beyond Price)

Duty-holders bear legal responsibility under EAWR 1989 for electrical equipment safety. Hiring cheap contractors doesn’t transfer this liability. While proper training develops testing competence through qualifications like City & Guilds 2377, genuine competence requires both technical knowledge and practical experience interpreting test results across different environments.

"PAT testing requires genuine competence under EAWR 1989—not just owning a £200 tester from eBay. You need to interpret insulation resistance readings, understand Class I versus Class II testing requirements, spot visual defects that indicate deeper problems, and make risk-based judgments about retest frequencies. City & Guilds 2377 provides the foundation, but competence comes from experience applying those standards across different environments."

Thomas Jevons, Head of Training

What to request from contractors:

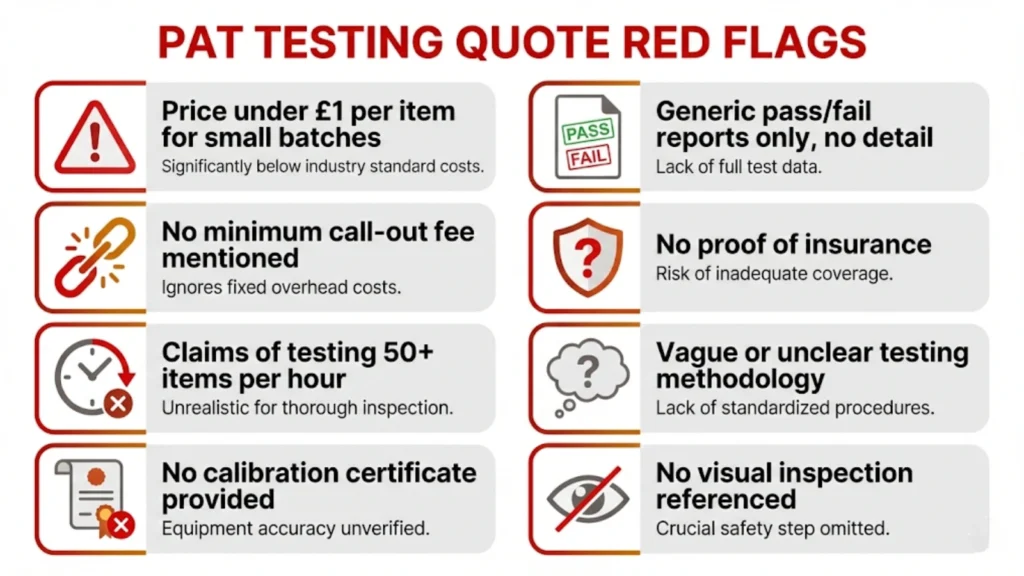

City & Guilds 2377 certificate or equivalent: This is baseline competence training for PAT testing. Contractors without formal training may miss critical defects or misinterpret test readings.

Calibration certificates: Request copies of current calibration certificates (dated within last 12 months) for PAT testing instruments. Uncalibrated testers produce unreliable results, potentially passing dangerous equipment.

Insurance documentation: Minimum £2 million public liability, preferably £5 million for larger sites. Professional indemnity insurance (£1-£2 million) covers errors in testing or reporting.

Sample reports: Ask for anonymized example of previous client reports. Look for:

- Detailed asset register with serial numbers, locations

- Individual test results (earth continuity readings, insulation resistance values)

- Visual inspection findings documented

- Risk-based retest frequency recommendations (not blanket “12 months”)

- Photographs of failed items with fault descriptions

References or case studies: Previous clients in similar environment (industrial, education, office) willing to verify quality and responsiveness.

Methodology statement: How do they handle failed items? Do they offer on-site repairs? What’s turnaround time for reporting? How do they manage asset tracking for large sites?

Questions to ask during quote process:

“How long will testing take?” Realistic answer for 50-item office: 4-6 hours including setup and reporting. Anyone suggesting 1-2 hours is skipping visual inspections.

“What’s included in your report?” Should include asset register, individual test results, photographs of failures, risk-based retest recommendations.

“What happens if equipment fails?” Do they offer on-site repairs (replacing fuses, fitting new plugs)? What’s the process for removing failed equipment from service?

“How do you determine retest frequencies?” Correct answer references risk assessment based on equipment type, usage environment, and user competence—not blanket “everything annually.”

“What’s your competence certification?” Should reference City & Guilds 2377 and practical experience. “I’ve been testing for 10 years” without qualification isn’t competence.

Red flags indicating inadequate service:

Price significantly below market average (e.g., £0.80 per item for small batch) suggests corners being cut somewhere—usually visual inspections or reporting.

No mention of visual inspection in scope of work—electrical testing alone misses 80-90% of faults.

Vague timelines like “we’ll knock it out in an hour” for 50+ items—physically impossible for compliant work.

Generic reports described as “just a pass/fail list”—inadequate for EAWR compliance evidence if incidents occur.

No minimum call-out fee for small jobs—indicates contractor doesn’t understand their own costs and likely provides poor service.

Reluctance to provide insurance or calibration certificates—suggests either lacking coverage or using uncalibrated equipment.

Promises of “fastest service” without discussing thoroughness—speed and compliance are often incompatible in PAT testing.

What good contractors do differently:

Pre-job risk assessment: Visit site or discuss via phone to understand equipment types, environment, access constraints, and appropriate retest frequencies.

Transparent pricing: Explain what’s included, why certain items cost more (110V, specialist equipment), and provide written breakdown.

Failed item management: Offer to repair simple faults on-site (fuses, plugs), provide clear labelling and removal procedures for items that can’t be repaired.

Asset management support: Help establish risk-based testing schedules, integrate with your existing asset tracking systems, provide training for staff on user checks.

Responsive communication: Answer questions about compliance obligations, provide guidance on EAWR requirements, explain test results in accessible language for non-technical staff.

The cheapest quote rarely provides this level of service. Your procurement decision should balance cost against compliance quality, contractor competence, and long-term risk management.

The Legal Reality: What EAWR 1989 Actually Requires

Misunderstanding electrical safety law drives unnecessary costs and creates false compliance confidence.

What the law says:

The Electricity at Work Regulations 1989, specifically Regulation 4(2), states:

“As may be necessary to prevent danger, all systems shall be maintained so as to prevent, so far as is reasonably practicable, such danger.”

What the law doesn’t say:

“All portable appliances must be tested annually.” “PAT testing is mandatory.” “Green stickers prove compliance.” “New equipment doesn’t need checking.”

The actual legal requirement:

Duty-holders (employers, landlords, building managers) must ensure electrical equipment is maintained in a safe condition. The method, frequency, and scope are determined by risk assessment, not arbitrary rules.

Risk-based frequency:

High-risk equipment (used frequently, harsh environments, mobile/portable, used by public):

Kettles, power tools, extension leads in offices: 6-12 months

Construction site 110V tools: 3-6 months

Portable heaters, kitchen equipment: 6-12 months

Medium-risk equipment (regular use, controlled environment, trained users):

Office IT equipment, desk lamps, printers: 2-4 years

Fixed workshop machinery: 2-3 years

Classroom audio-visual equipment: 1-2 years

Low-risk equipment (occasional use, low power, double-insulated):

Battery chargers, monitors, desk fans: 4-5 years

Sealed LED lighting, low-power electronics: 5 years or user checks only

User checks vs formal inspection vs combined testing:

User checks (daily/weekly): Staff visually check equipment before use—damaged cables, loose plugs, strange smells, unusual operation. No training required beyond basic awareness. Catches immediate hazards.

Formal visual inspection (6-24 months): Competent person thoroughly examines equipment without electrical testing—looking for damage, incorrect fusing, wear patterns. Finds 80-90% of faults.

Combined inspection and testing (12 months-5 years): Full visual inspection plus electrical testing using PAT instrument. Required frequency depends on risk assessment, not calendar date.

Many organizations over-test low-risk equipment (wasting money testing monitors annually) while under-testing high-risk equipment (kettles in busy offices going 2-3 years without checks).

What constitutes compliance evidence:

If an incident occurs and HSE investigates, you must demonstrate you took “all reasonable steps” to prevent danger. This means:

Risk assessment documentation: Written record of how you determined testing frequencies for different equipment types based on usage, environment, and user competence.

Asset register: Complete inventory of equipment, including serial numbers, locations, purchase dates, and test history.

Test records: Results of inspections and testing, including specific readings (not just “pass”), findings, and actions taken for failed items.

Failed item management: Documentation of how you removed dangerous equipment from service, repaired or replaced it, and prevented continued use.

Staff training records: Evidence that users know to report damage and stop using faulty equipment.

Green stickers alone do not prove compliance. They’re administrative conveniences. The asset register and detailed test records are the legal evidence.

Contractor relationship to duty-holder:

Hiring a PAT contractor does not transfer your EAWR 1989 responsibility. You remain the duty-holder. The contractor is a service provider helping you meet your obligations.

If the contractor provides inadequate testing (skips visual inspections, uses uncalibrated equipment, produces dummy data in reports), you are still liable if equipment causes injury or fire.

This is why procurement decisions based solely on lowest price are legally risky. If your £0.70 per item contractor missed an obvious cable fault that caused a fire, your insurance may challenge whether you exercised reasonable duty of care in contractor selection.

Prosecution examples:

HSE prosecutions for electrical safety failures typically cite inadequate maintenance systems, not absence of PAT testing specifically. However, inability to produce risk assessment documentation, asset registers, or testing records is cited as evidence of poor maintenance.

Fines for companies range from £10,000 for small businesses to £1,000,000+ for large organizations where electrical failures cause serious injury or death. Duty-holders personally can face imprisonment in extreme cases.

The legal defense isn’t “we had PAT testing done.” It’s “we conducted risk-based maintenance appropriate to our circumstances, documented our approach, used competent contractors, and responded appropriately to identified hazards.”

Regional Pricing Variations Across the UK

Operating costs vary significantly by region, creating genuine pricing differences that aren’t arbitrary.

London and South East:

Typical rates: £2.50-£5.00 per item, £90-£120 minimum call-out, £350-£500 day rate

Cost drivers:

- Congestion charge and parking costs (£15-£30 per site visit)

- Higher fuel costs and longer travel times through traffic

- Commercial rent and business rate premiums (30-50% higher than Midlands)

- Wage expectations reflecting cost of living (electricians £40,000-£55,000 versus £32,000-£42,000 Midlands)

- Higher insurance premiums due to claim frequency and costs

Market reality: London contractors competing at Midlands rates either work at a loss or cut corners. The premium isn’t profiteering—it reflects genuine operating cost differences.

Midlands (Birmingham, Coventry, Wolverhampton, Leicester):

Typical rates: £1.80-£3.00 per item, £60-£90 minimum call-out, £250-£350 day rate

Cost drivers:

- Moderate transport costs and parking

- Competitive commercial property costs

- Electrician wages around national median (£35,000-£42,000)

- Insurance costs slightly below national average

- Mix of industrial and commercial work providing volume

Market position: Birmingham sits between London’s premium and Northern England’s lower baseline. Electricians can achieve sustainable businesses at £2.00-£2.50 per item rates with proper volume.

Northern England, Scotland, Wales:

Typical rates: £1.50-£2.50 per item, £50-£80 minimum call-out, £200-£300 day rate

Cost drivers:

- Lower commercial property and operating costs

- Reduced fuel and parking expenses (less congestion)

- Electrician wage expectations £30,000-£38,000

- Lower insurance premiums reflecting claim patterns

- More competitive market in some areas with greater contractor supply

Market challenges: Lower rates can still support quality work given reduced overheads, but ultra-competitive markets (multiple contractors in small towns) sometimes drive unsustainable pricing.

Rural and remote areas:

Typical rates: Often higher than nearest urban center due to travel time

Cost drivers:

- Extensive travel distances between jobs (2-3 hours round trip common)

- Lower client density means can’t chain multiple jobs per day

- Fuel costs represent larger proportion of total

- Limited contractor supply in some areas

Market reality: Rural businesses in Highlands, mid-Wales, or Cornwall may charge £3.00-£4.00 per item not due to greed but because serving 5 clients per week with 2-hour drives each isn’t viable at urban rates.

Why regional comparison shopping fails:

Clients sometimes solicit quotes from contractors 50-100 miles away seeing lower advertised rates, then express frustration when the contractor adds travel premiums or declines the work entirely.

A Birmingham contractor can’t sustainably serve London at Birmingham rates when the M1 travel adds 3-4 hours to the job. A London contractor can’t compete with Birmingham rates in the Midlands because their operating costs are fundamentally higher. Broader policy uncertainty impacts contractor strategies beyond just regional variations—regulatory changes, insurance premium volatility, and economic uncertainty all affect business planning and pricing stability. Regional pricing differences reflect genuine economic realities. Procurement managers should compare quotes within their region, not against national averages that mask substantial cost structure variations.

Decision Framework: How to Price or Purchase PAT Services

Different stakeholders require different approaches.

For sole traders and small electrical contractors:

Start with your target hourly rate: Calculate what you need to earn per hour to cover all business costs and provide reasonable profit. For most electrical contractors, this is £30-£50/hour depending on region and overhead structure.

Calculate job time realistically: Small office (30 items) = 1.5 hours travel + 4 hours testing + 1.5 hours reporting = 7 hours total. At £35/hour target, that’s £245 minimum viable revenue.

Structure your quote: £75 minimum call-out + £2.50 per item = £150 total. This generates £21.43/hour effective rate—below target but acceptable for relationship building. Never go below £20/hour effective rate after all costs.

Don’t compete with national providers: You cannot match £0.70 per item rates of companies doing 500+ tests per week with dedicated admin staff and multi-van operations. Instead, position on:

- Local service and responsiveness

- Ability to repair failed items on-site

- Personal relationship with the duty-holder

- Quality reporting tailored to their compliance needs

- Knowledge of their specific equipment and environment

"Competing with national £0.70 per item providers is a race to the bottom that sole traders can't win sustainably. Instead, position on competence, local service, ability to repair failed items on-site, and quality reporting. Clients who genuinely understand compliance value these factors over rock-bottom pricing. The duty-holder's legal responsibility doesn't disappear because they hired cheap testing—when incidents occur, inadequate PAT documentation exposes them to significant liability."

Joshua Jarvis, Placement Manager

Bundle services: Offer PAT testing combined with EICR, emergency lighting tests, or general electrical maintenance. This amortizes travel costs and provides better value to client.

Build contract relationships: Annual contracts with predictable visits provide guaranteed work and allow lower per-visit pricing because you’re not constantly acquiring new clients.

For companies and facilities managers purchasing PAT services:

Create vendor scorecard:

- Competence: 30% weight (qualifications, insurance, calibration certificates)

- Reporting quality: 25% weight (sample reports, asset management capability)

- Price competitiveness: 25% weight (but not sole criterion)

- Service quality: 20% weight (responsiveness, failed item management, methodology)

Evaluate total cost of compliance, not just per-item rate:

Contractor A: £0.90 per item, no minimum, vague reporting, no repair capability

- Appears cheapest per item

- But requires separate repair call-outs for failed items (£80-£120 each)

- Poor reporting means manual work creating compliant asset register (2-3 hours admin time)

- Total cost: Higher than apparent

Contractor B: £2.20 per item + £75 minimum, comprehensive reporting, on-site repairs included

- Higher per-item rate

- But includes minor repairs in price

- Professional reporting saves admin time

- Total cost: Lower and better compliance quality

Negotiate risk-based contracts: For large facilities, work with contractor to establish risk-based testing frequencies rather than blanket annual. This reduces unnecessary testing while maintaining compliance.

For facilities managers comparing multiple quotes:

Request detailed scope of work from each contractor:

- Exactly what’s included (visual inspection, electrical testing, labelling, reporting)

- Methodology (how they determine pass/fail, handling of failed items)

- Deliverables (report format, asset register, photographic evidence)

- Timelines (turnaround for report delivery, scheduling flexibility)

Check references: Contact previous clients in similar environments. Ask about contractor thoroughness, report quality, responsiveness to questions, handling of failed items.

Conduct trial engagement: For large multi-site organizations, consider trial period with one site before committing to full contract. This validates contractor quality before scaling.

For landlords vs commercial duty-holders:

Landlords (HMOs, rental properties):

Focus on cost-effective compliance for low-risk domestic equipment. Priority is meeting legal obligations for tenant safety.

Recommended approach:

- £40-£100 per property depending on item count

- Bundle with EICR (required every 5 years for rental properties)

- Basic but compliant reporting showing due diligence

- Annual or biennial frequency depending on property type and tenancy turnover

Commercial duty-holders (offices, retail, industrial):

Focus on comprehensive risk management for varied equipment and usage patterns. Priority is protecting staff, customers, and business from electrical incidents.

Recommended approach:

- £1.80-£3.00 per item or day rate for larger sites

- Risk-based frequency planning (not blanket annual)

- Comprehensive asset management and reporting

- Integration with broader facilities management systems

- Regular contractor review to ensure quality maintenance

Common Myths About PAT Testing Pricing

Several persistent misconceptions distort market expectations.

Myth: “£1 per item is normal and sustainable.”

Reality: Ultra-low pricing is economically impossible for compliant work once you account for 20-30% travel time, 5-10 minutes per item for proper visual and electrical testing, 1-2 hours reporting, plus calibration, insurance, and business overheads. Contractors offering these rates either operate at high volume (500+ items per week) where economies of scale apply, or skip critical steps like visual inspections and comprehensive reporting.

Myth: “PAT testing is a legal requirement with fixed annual frequency.”

Reality: EAWR 1989 requires safe maintenance, not PAT testing specifically. Frequency depends on risk assessment—high-risk equipment may need 6-month testing, low-risk equipment may go 4-5 years. Annual testing of all equipment regardless of risk wastes money while potentially missing genuine hazards in high-risk items.

Myth: “Anyone with a PAT tester can do the work.”

Reality: Competence requires technical knowledge to interpret insulation resistance readings, understand Class I/II testing differences, spot visual defects indicating deeper problems, and make risk-based judgments about retest frequencies. City & Guilds 2377 provides baseline training, but competence comes from experience across different environments. EAWR 1989 requires “competent persons”—equipment ownership doesn’t equal competence.

Myth: “The green sticker proves legal compliance.”

Reality: Labels are administrative conveniences with no legal standing. The asset register and detailed test records (including individual readings, visual inspection findings, and failed item management) constitute legal compliance evidence if HSE investigates. Many inadequate contractors provide labels without producing usable documentation.

Myth: “All PAT testing is the same regardless of price.”

Reality: Price differences reflect methodology quality. £0.80 per item contractors typically skip visual inspections (where 80-90% of faults are found), use uncalibrated equipment, produce generic pass/fail lists without detailed findings, and lack adequate insurance. £2.50-£3.00 per item contractors conduct thorough visual inspections, use calibrated equipment, provide comprehensive reporting with specific readings and photographs, and carry proper insurance for liability protection.

Myth: “New equipment doesn’t need testing.”

Reality: New equipment should receive initial inspection and be added to asset register immediately. Manufacturing defects exist, and equipment can be damaged during delivery or installation. The first formal test might be 2-4 years away depending on risk assessment, but visual checks and asset documentation begin immediately.

Myth: “PAT testing is just a revenue generator for electricians.”

Reality: When conducted properly with risk-based frequency planning, PAT testing prevents electrical fires and shocks while providing legal compliance evidence under EAWR 1989. The problem is mandatory annual testing of low-risk equipment (which is unnecessary) being sold as compliance requirement. Proper risk-based testing is neither over-testing nor under-testing—it’s appropriate maintenance.

Myth: “I can do it myself to save money.”

Reality: You can purchase PAT testers and conduct testing if you develop competence (training, experience, understanding of regulations). However, most duty-holders lack the time, training, and understanding to conduct compliant testing. The liability risk of inadequate self-testing (missing faults, producing non-compliant documentation) often exceeds the cost of hiring competent contractors.

PAT Testing in Sustainable Electrical Business Models

Understanding PAT’s role in broader business strategy helps both electricians and clients.

For electricians:

PAT as relationship building: Small PAT jobs (£75-£150) rarely generate significant profit directly. Their value is establishing client relationships leading to higher-value work:

Emergency call-outs (£80-£150 per call)

Electrical installation work (£300-£2,000+ per job)

EICR testing (£150-£400 per property)

Ongoing maintenance contracts (£500-£5,000+ annually)

PAT as capability demonstration: Thoroughness on small PAT jobs demonstrates competence and reliability. Clients notice when you explain risk-based frequencies instead of automatically recommending annual testing, when you repair failed items on-site instead of just labelling them, when your reports are detailed and professional. This builds trust for larger electrical projects.

PAT as training ground: Newly qualified electricians or apprentices can develop PAT competence under supervision, building confidence with client interaction, report writing, and systematic testing methodology before progressing to more complex electrical work.

For clients:

PAT as risk management tool: Properly conducted PAT testing with risk-based frequency planning protects against electrical fires, shock injuries, business interruption from equipment failures, and HSE prosecution if incidents occur. The cost (£200-£1,000 annually for most businesses) is insignificant compared to potential fire damage (£50,000-£500,000+) or injury compensation claims (£10,000-£1,000,000+).

PAT as asset management: Quality PAT reporting provides comprehensive equipment inventory, identifies aging equipment before failure occurs, supports replacement budgeting, and documents maintenance history for insurance purposes.

PAT as compliance evidence: EAWR 1989 places legal duty on employers and landlords to maintain electrical equipment. Professional PAT documentation demonstrates due diligence, protects against HSE prosecution, and supports insurance claims if incidents occur despite reasonable precautions.

The sustainability equation:

Electricians: Charge rates that cover actual costs + reasonable profit → maintain quality standards → build client relationships → generate repeat business and referrals → sustainable long-term business

Clients: Pay fair rates for competent contractors → receive thorough testing and quality documentation → reduce electrical incidents and liability → save money on reduced failures and insurance claims → better long-term value than cheap inadequate testing

The race-to-the-bottom pricing model damages both parties. Electricians burn out or cut corners, creating liability exposure. Clients get inadequate testing that fails to prevent incidents, exposing them to legal and financial consequences.

Get Pricing Right: Sustainable Compliance for Everyone

Call us on 0330 822 5337 to discuss PAT testing pricing strategies, understand how to structure quotes that cover actual costs while remaining competitive, learn what safety managers should look for beyond lowest price, and explore risk-based testing frequencies that maintain compliance without unnecessary annual testing.

What we’re not going to tell you:

- That £0.80 per item is viable for quality work (it isn’t)

- That annual testing is legally mandatory (EAWR requires risk-based maintenance)

- That the cheapest quote is the best value (it rarely is)

- That competence comes from just owning a PAT tester (it requires training and experience)

What we will tell you:

- Why proper PAT work takes 5-10 minutes per item when including visual inspection, electrical testing, labelling, and documentation

- How to calculate sustainable pricing covering travel/setup 20-30%, testing time, reporting 1-2 hours, calibration £100-£200 annually, and insurance £500+

- Why visual inspection finds 80-90% of faults, making rushed “electrical testing only” approaches dangerously inadequate

- How regional pricing differences (London £2.50-£5.00 versus Midlands £1.80-£3.00 versus North £1.50-£2.50) reflect genuine operating cost variations

- Why EAWR 1989 requires risk-based frequencies (high-risk 6-12 months, low-risk 4-5 years), not blanket annual testing wasting money

- How duty-holders retain legal liability regardless of contractor quality, making procurement decisions based solely on price legally risky

- What City & Guilds 2377 competence actually means and why experience across environments matters beyond just qualification certificates

- Why comprehensive asset registers and detailed test records (not green stickers) constitute legal compliance evidence if HSE investigates incidents

For electricians: Structure pricing with minimum call-out £60-£100 for small jobs, per-item rates £2.00-£3.00 reflecting actual work time, or day rates £250-£400 for complex sites. Position on competence, local service, repair capability, and quality reporting rather than competing with national £0.70 providers through unsustainable undercutting.

For safety managers: Evaluate quotes on competence proof (City & Guilds 2377, insurance, calibration certificates), reporting quality (asset registers, individual readings, risk-based recommendations), and contractor methodology (visual inspections included, failed item management, retest planning) rather than selecting lowest per-item rate that likely indicates inadequate work.

No promises that PAT testing is quick revenue. No encouragement of race-to-bottom pricing destroying sustainable businesses. Just honest guidance on what compliant work actually costs, why corners get cut when pricing drops too low, and how both electricians and clients benefit from fair rates supporting thorough testing rather than cheap inadequate services creating liability exposure for everyone.

References

Primary Official Sources

- Electricity at Work Regulations 1989: https://www.legislation.gov.uk/uksi/1989/635/contents

- HSE Guidance INDG236 – Maintaining Portable Equipment: https://www.hse.gov.uk/pubns/indg236.pdf

- HSE FAQs on Portable Appliance Testing: https://www.hse.gov.uk/electricity/faq-portable-appliance-testing.htm

- HSE Guidance on Electrical Safety: https://www.hse.gov.uk/electricity/experience.htm

Industry Standards and Best Practice

- IET Code of Practice for In-Service Inspection and Testing (5th Edition): https://electrical.theiet.org/bs-7671/code-of-practice-for-in-service-inspection-and-testing-of-electrical-equipment-5th-edition/

- NICEIC Guidance on PAT Testing: https://niceic.com/householders/electrical-services/portable-appliance-testing

- ECA Risk-Based PAT Approach: https://www.eca.co.uk/taking-action/skills-for-the-future

- Electrical Safety First Best Practice Guides: https://www.electricalsafetyfirst.org.uk

Training and Competence

- City & Guilds 2377 PAT Testing Qualification: https://www.cityandguilds.com

- Skills Training Group PAT Competence Guidance: https://www.skillstg.co.uk/blog/pat-testing-insurance-requirements

Market Pricing Research (Qualitative)

- Checkatrade PAT Testing Cost Guide 2026: https://www.checkatrade.com/blog/cost-guides/pat-testing-cost/

- MyJobQuote PAT Testing Pricing: https://www.myjobquote.co.uk/costs/pat-testing-cost

- Electrician Forums – PAT Pricing Discussions: https://www.electriciansforums.net

- Community Screwfix PAT Rates Thread: https://community.screwfix.com/threads/pat-testing-prices.30373

Insurance and Liability

- Castlemead Insurance – PAT Contractor Requirements: https://www.castlemead.com

- HSE Prosecution Database – Electrical Safety Cases: https://press.hse.gov.uk

Note on Accuracy and Updates

Last reviewed: 02 February 2026. This page is maintained; we correct errors and refresh sources as market rates, EAWR compliance guidance, and industry best practices change. Pricing ranges (London £2.50-£5.00, Midlands £1.80-£3.00, North £1.50-£2.50 per item) reflect 2026 market observations from advertised rates, electrician forums, and procurement discussions—not official statistics. Regional cost drivers (wages, transport, insurance) justify variations. EAWR 1989 legal requirements remain stable (safe maintenance, risk-based approach), but HSE guidance interpretation evolves. Competence standards (City & Guilds 2377), calibration requirements (annual), and insurance minimums (£2-£5 million public liability) reflect current industry expectations. Next review scheduled following any significant changes to electrical safety regulations, insurance requirements, or substantial market rate shifts.

FAQs

What’s a realistic price per item for PAT testing in 2026?

In 2026, a realistic price per item for PAT testing in the UK generally falls between £1.50 and £3, influenced by factors such as job size and regional variations.

For smaller quantities (under 50 appliances), rates often sit at the higher end to account for fixed costs like travel and setup time. Larger volumes can attract discounts, reducing the cost to around £1 to £2 per item as efficiencies improve.

These figures reflect common industry practice, where pricing must cover engineer expertise, calibrated equipment, and administrative tasks. As the duty holder, prioritise value and thorough testing rather than the lowest quote, to ensure appliances are properly checked and maintained.

Why is “per item” pricing misleading for PAT testing?

Per-item pricing can be misleading because it often excludes additional charges that appear later, increasing the final cost unexpectedly.

Common extras include:

- Microwave leakage testing

- Plug rewiring

- Fuse replacement

Appliances also vary in complexity and accessibility, meaning a single flat rate rarely reflects the real time required. Very low per-item prices can indicate rushed inspections where visual or electrical tests are reduced to maintain margins.

As the duty holder, request transparent quotes that clearly state inclusions, minimum charges, and potential add-ons to ensure safety standards are not compromised.

Is £1.50 per item ever viable for compliant PAT testing?

Yes, £1.50 per item can be viable in specific circumstances, particularly for high-volume jobs (100+ simple appliances) such as office environments.

In these cases, scale allows contractors to work efficiently while maintaining compliance. However, for smaller batches or complex environments with industrial equipment, this rate may encourage rushed testing.

Viability depends on whether the price includes:

- Full visual inspections

- Electrical measurements

- Labelling

- Basic remedial work

As the duty holder, confirm the contractor’s process and reputation to ensure quality is not sacrificed for price.

How many items per hour is realistic, and why is “50 items per hour” a red flag?

A realistic PAT testing rate is 15 to 30 items per hour.

This allows time for:

- Visual inspections

- Electrical testing

- Labelling

- Data entry

Simple items like desk lamps are faster, while larger or fixed appliances take longer. Claims of 50 items per hour suggest inspections may be superficial, increasing the risk of missed faults.

As the duty holder, choose providers who emphasise methodical testing rather than extreme speed.

Should I charge a minimum call-out fee for small PAT jobs?

Yes. A minimum call-out fee is practical and industry-standard.

Typical fees range from £50 to £100, often including testing for the first 10 to 20 items. This covers unavoidable costs such as travel, setup, and paperwork.

Without a minimum fee, small jobs become uneconomical and may lead to rushed or incomplete work. This pricing structure supports both provider sustainability and duty holder safety obligations.

When should I quote a day rate instead of a per-item rate?

A day rate is preferable when:

- Sites are large or complex

- Appliance numbers are high

- Access is restricted

- On-site repairs are likely

Day rates typically fall between £200 and £300 in the UK. This approach removes pressure to rush and allows thorough inspections without counting every item.

For duty holders, day rates provide cost certainty and consistent quality on complex sites.

Why do PAT testing prices vary between London and the Midlands?

Regional price differences reflect operating costs.

- London: £2 to £4 per item

- Midlands: £1 to £2.50 per item

Higher wages, congestion, transport costs, and overheads drive London pricing. Midlands rates benefit from lower operating expenses.

Regardless of location, duty holders should prioritise competence and documentation over price alone.

What should a safety manager ask a PAT contractor to provide before awarding the job?

A safety manager should request:

- Proof of qualifications (e.g. City & Guilds 2377)

- Public liability insurance (typically £5m+)

- Calibration certificates for test equipment

- Sample PAT reports with detailed results

- Method for handling failed items

- References from similar UK clients

This due diligence supports duty holder accountability and ensures appliances are tested competently.

What does good PAT documentation look like, and how long should reporting take?

Good PAT documentation includes:

- Appliance description and ID

- Location

- Test date

- Visual and electrical test results

- Pass/fail status with measured values

- Recommended retest intervals

Reports should be clear, digital, and audit-ready. Reporting typically takes 15–30 minutes per 50 items, with same-day delivery achievable using modern systems.

These records demonstrate active management of electrical safety.

If my contractor is cheap, does that reduce my legal responsibility under EAWR 1989?

No. Choosing a cheaper contractor does not reduce your legal responsibility as the duty holder.

You remain fully accountable for the safe condition of electrical equipment. If testing is inadequate, liability still rests with you.

Low prices can hide risks such as missed defects or incomplete inspections. Always verify competence, process, and documentation. Cost savings must never compromise safety or compliance.