Electrical Fault-Finding Courses: What You Should Know Before Training

- Technical review: Thomas Jevons (Head of Training, 20+ years)

- Employability review: Joshua Jarvis (Placement Manager)

- Editorial review: Jessica Gilbert (Marketing Editorial Team)

- Last reviewed:

- Changes: Updated 2025 course tier pricing and EAS 2024 competence requirements

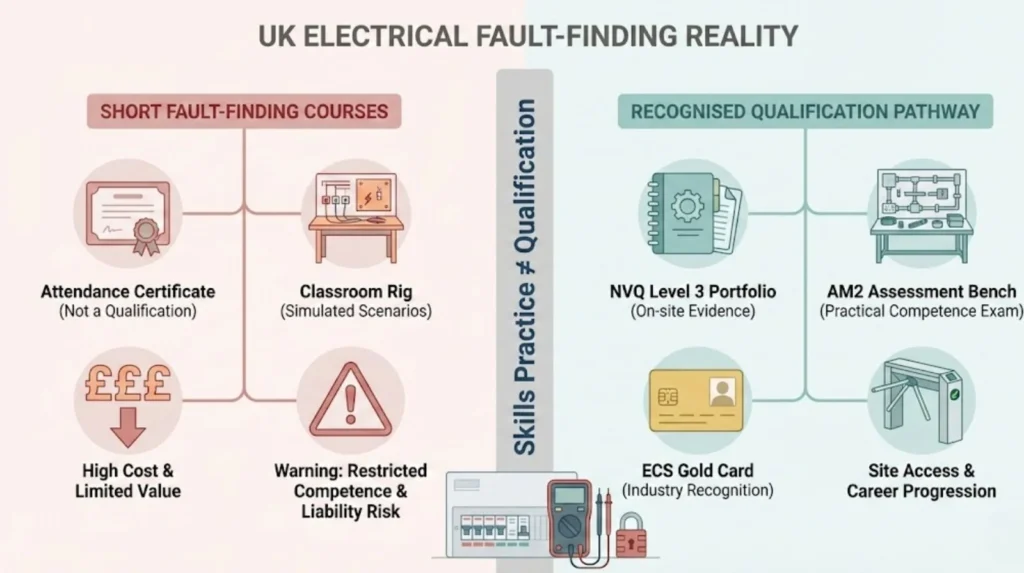

The electrical training market sells “fault-finding courses” as if they’re qualifications. They’re not. This is where people get tripped up most often, spending £200-£950 on courses expecting employability credentials but receiving attendance certificates with no industry recognition for site access or insurance purposes.

Fault-finding is a diagnostic skill embedded within NVQ Level 3 portfolios and assessed formally in the AM2 end-point test. It’s not a standalone qualification you can acquire through short courses, regardless of marketing claims suggesting otherwise. Understanding this distinction before paying for training prevents wasted investment and dangerous overconfidence in safety-critical work.

Genuine fault-finding competence requires electrical theory knowledge, safe isolation procedures, systematic testing methodology, and extensive site experience. Short courses provide practice environments and skill refinement, which helps qualified electricians upskill or NVQ learners prepare for assessments. They don’t create competence from scratch, and they don’t substitute for formal qualifications when employers check credentials or insurers assess liability.

This article explains what fault-finding actually means in UK electrical contexts, where it fits in qualification pathways, what courses realistically deliver, and how to avoid misleading marketing that conflates attendance certificates with legal competence. If you’re considering complete UK electrician course options including proper qualification routes, understanding fault-finding’s role within formal training prevents expensive detours through courses that don’t advance your credential status.

What "Fault-Finding" Actually Means in UK Electrical Work

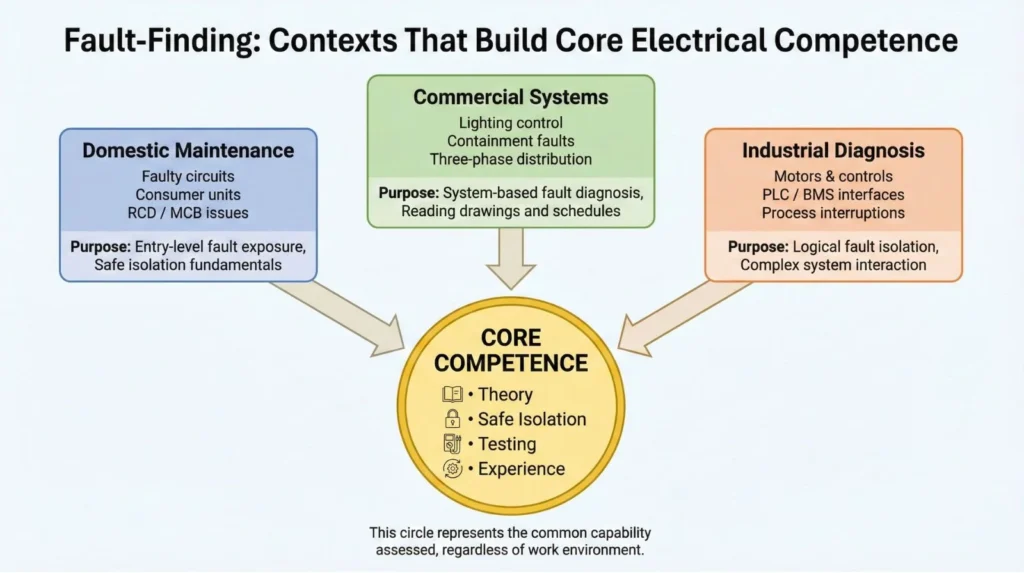

First, clarity on terminology. Fault-finding describes diagnostic processes identifying why electrical systems aren’t functioning correctly, then implementing safe corrective measures. The work varies dramatically by context, and those contexts determine what competence demonstration looks like.

Domestic maintenance fault-finding covers problems in residential properties: RCDs tripping repeatedly, lighting circuits failing, socket outlets with no voltage, or consumer units showing fault indicators. Diagnosis involves interpreting symptoms, isolating circuits safely, testing systematically with appropriate equipment, and determining whether problems stem from wiring deterioration, faulty accessories, overloaded circuits, or external factors like dampness affecting connections.

Commercial and industrial fault diagnosis operates at different scales and complexity. Commercial buildings involve distribution boards serving multiple floors, three-phase supplies, lighting control systems, fire alarm integration, and emergency power circuits. Industrial environments add motor control circuits, automation systems, PLC integration, and high-current distribution requiring specialized diagnostic approaches. Problems might involve faulty contactors, sensor failures, control logic errors, or thermal overload protection activation.

Assessment-based fault diagnosis appears in two formal qualification contexts. The AM2 (Achievement Measurement 2) practical assessment includes Section C where candidates diagnose planted faults in realistic test circuits under timed examination conditions. This assesses whether learners can apply systematic troubleshooting to unfamiliar problems without guidance. NVQ Level 3 portfolios require workplace evidence demonstrating candidates identified genuine faults in real installations, tested safely, diagnosed root causes, and rectified problems under assessor observation.

These aren’t separate qualification categories. They’re contexts where the same underlying competence applies: understanding electrical principles, following safe isolation procedures per HSE guidance GS38, using calibrated test equipment correctly, interpreting measurements against expected values, and making informed decisions about remedial actions. Short fault-finding courses simulate these scenarios but don’t assess competence formally or create credentials recognized by employers, insurers, or scheme providers.

The Electricity at Work Regulations 1989 require “competence” for any work on electrical systems, with competence defined as adequate knowledge, skills, and experience for the specific work undertaken. Attending a fault-finding course provides knowledge and some skills practice. It doesn’t provide the experience component or the formal assessment proving you can apply those skills safely under realistic pressures.

The Qualification Reality (Where Fault-Finding Actually Sits)

Understanding formal qualification pathways clarifies where fault-finding courses fit. Spoiler: they sit outside the main pathway as optional supplements, not essential components.

Level 2 Diploma (City & Guilds 2365-02 or equivalent) teaches fundamental installation principles, circuit design, and basic testing procedures. Learners gain theoretical understanding of Ohm’s Law, circuit protection devices, and earthing systems. What Level 2 doesn’t provide is diagnostic competence or the practical experience distinguishing normal operation from fault conditions. It’s foundational knowledge, not applied troubleshooting ability.

Level 3 Diploma (2365-03) extends complexity into three-phase systems, larger installations, and more advanced testing procedures including insulation resistance, earth loop impedance, and RCD operation verification. The syllabus introduces fault scenarios as teaching examples, but diploma completion doesn’t prove you can diagnose unfamiliar problems independently. That proof comes later in the pathway.

NVQ Level 3 (2357 Electrotechnical Technology) requires workplace portfolio evidence demonstrating competence across multiple installation and maintenance tasks. This includes Units covering fault diagnosis and rectification in real installations under assessor observation. Portfolio requirements demand photographs, test results, and assessor witness statements confirming you identified problems, applied systematic diagnostic procedures, and implemented safe corrections.

Thomas Jevons, Head of Training:

"NVQ Level 3 requires workplace evidence of diagnosing and rectifying real faults in genuine electrical installations. Your assessor needs photographs and observation records showing you identified problems, tested systematically, and implemented safe solutions. Classroom-based fault-finding courses using training rigs don't provide this evidence. They build skills, but they're not portfolio-worthy documentation for NVQ units. You still need genuine site-based fault diagnosis witnessed by your assessor."

Thomas Jevons, Head of Training

AM2/AM2E/AM2S Assessment serves as the end-point practical examination for electrical installation qualifications. Section C specifically tests fault-finding ability through planted faults in circuits candidates must diagnose within time limits using systematic approaches. Success demonstrates you can troubleshoot unfamiliar problems without supervision or guidance. This formal assessment carries industry recognition; short-course certificates don’t.

ECS Gold Card (Installation or Maintenance Electrician) requires NVQ Level 3 plus successful AM2 completion. The card provides site access on major construction and industrial projects, proving to employers you hold formally-assessed competence. Most recruitment specifications for electrical roles state “Gold Card essential” or “NVQ Level 3 required.” Fault-finding course certificates don’t satisfy these requirements regardless of course duration or content quality.

City & Guilds 2391-52 (Inspection and Testing) often gets confused with fault-finding qualifications. It’s not. The 2391 qualification covers periodic inspection procedures, initial verification testing, and identifying non-compliances with BS 7671 requirements. Whilst inspection work involves identifying faults, the focus is verification against standards rather than diagnostic troubleshooting. The 2391 unlocks ability to sign off Electrical Installation Condition Reports legally; it doesn’t specifically train fault diagnosis beyond what’s necessary for inspection work.

Short fault-finding courses sit outside this qualification structure entirely. They provide skills practice useful for NVQ learners preparing for portfolio evidence collection or qualified electricians refining diagnostic techniques. They’re continuing professional development, not qualification components. Marketing suggesting otherwise misleads prospective learners about credential value.

What Fault-Finding Courses Actually Are (The Reality Check)

Let’s be direct: commercial fault-finding courses are practice sessions, not qualifications. They offer access to training rigs simulating common faults, instructor demonstrations of systematic diagnostic approaches, and supervised practice using test equipment. What they don’t offer is formal competence assessment, industry-recognized credentials, or evidence acceptable for NVQ portfolios.

Most courses run 1-5 days depending on complexity level. Learners practice diagnosing planted faults in circuits built specifically for training purposes. Instructors explain logical troubleshooting sequences: understanding circuit design, predicting expected values, measuring actual values, comparing results, hypothesizing causes, and testing hypotheses systematically until problems are isolated.

This methodology helps. It doesn’t create competence independently. The training rig environment differs fundamentally from real installations where circuits serve multiple purposes, wiring may be decades old with undocumented modifications, and problems might stem from deterioration, damage, overloading, or interference rather than single clear faults. Site experience working through genuine diagnostic challenges develops the pattern recognition distinguishing competent electricians from course attendees.

Certificates issued after course completion state attendance and perhaps successful completion of practical exercises. They don’t certify competence for independent electrical work. Employers and insurers understand this distinction even if marketing materials blur it deliberately. Recruitment specifications ask for NVQ Level 3 and Gold Card, not fault-finding course certificates, because only formal qualifications provide verified competence evidence.

The appropriate framing for these courses is continuing professional development for people who already hold core qualifications. A qualified electrician wanting to develop industrial three-phase diagnostic skills benefits genuinely from advanced fault-finding training. An improver with Level 2 hoping the course will substitute for Level 3 and NVQ misunderstands what’s being purchased and faces disappointment when attempting to convert course attendance into employment.

Joshua Jarvis, Placement Manager:

"We've seen people complete two-day fault-finding courses and immediately attempt complex diagnostics on domestic rewires or commercial installations without adequate supervision. The course gave them enough knowledge to feel confident but not enough experience to recognize when they're out of their depth. That confidence gap creates serious safety risks. Fault-finding courses work best for electricians who already have solid foundations and are adding diagnostic refinement, not for beginners trying to shortcut proper training."

Joshua Jarvis, Placement Manager

Typical Course Tiers (UK Market Reality 2025)

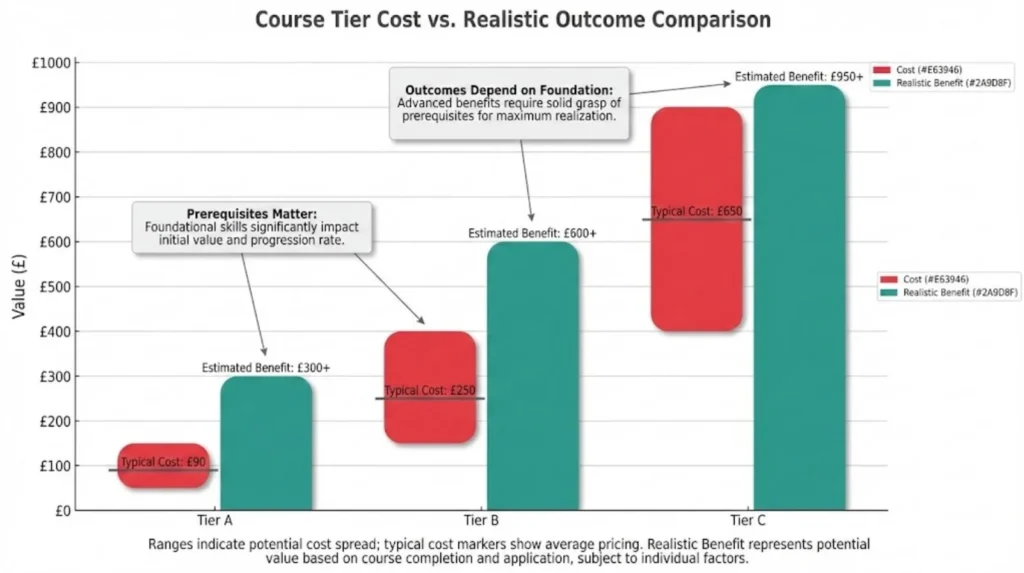

The UK training market offers fault-finding courses across three broad tiers. Understanding differences prevents paying for unsuitable content.

Tier A: Beginner/Improver Level

Typical duration: 1-2 days

Cost range: £150-£350

Prerequisites: Basic electrical knowledge, literacy and numeracy

Content: Safe isolation principles, circuit identification, simple testing on training rigs, introduction to multimeters and basic test equipment

Who benefits: Level 2 students gaining context for theoretical learning, improvers familiarizing with diagnostic concepts before site work

Who doesn’t: People expecting employment credentials or independent working authorization. These courses build awareness; they don’t create competence for unsupervised electrical work.

Realistic outcome: Understanding of systematic approaches, practice interpreting basic test results, foundation for further learning. Marketing exaggerations include claims like “master fault-finding techniques” or “become confident in diagnostics.” You’ll understand concepts; you won’t be competent for independent work.

Tier B: Maintenance/Service Level

Typical duration: 2-5 days

Cost range: £350-£600

Prerequisites: Prior electrical experience, Level 2 equivalent knowledge minimum

Content: Single and three-phase fault scenarios, motor testing, control circuits, distribution board problems, systematic diagnostic procedures

Who benefits: Maintenance operatives in facilities roles, NVQ learners preparing for portfolio evidence, qualified electricians entering maintenance specialisms

Who doesn’t: Complete beginners without electrical foundations, people expecting the course to replace NVQ requirements or create site access credentials

Realistic outcome: Improved diagnostic methodology, practice on realistic fault scenarios, better preparation for NVQ evidence collection or AM2 assessment. Marketing claims about “reducing downtime” or “increasing efficiency” assume you already work in roles where diagnostic skills apply. The course doesn’t create employment; it enhances existing roles.

Tier C: Advanced/Industrial Diagnosis

Typical duration: 5+ days

Cost range: £600-£950

Prerequisites: Industrial electrical experience, knowledge of PLCs, drives, and control systems recommended

Content: Three-phase systems, PLC integration, inverter drives, industrial control panels, root cause analysis, complex diagnostic sequences

Who benefits: Qualified electricians specializing in industrial roles, maintenance engineers supporting process plant, technicians working with automation systems

Who doesn’t: Electricians without industrial exposure, people lacking formal qualifications hoping advanced courses substitute for NVQ/AM2 pathways

Realistic outcome: Enhanced specialist diagnostic skills in industrial contexts, better understanding of complex system integration. Exaggerations include “become an expert in weeks.” Expertise develops over years of varied experience; courses accelerate learning within existing competence frameworks.

| Tier | Duration | Cost | Prerequisites | Realistic Benefit | Common Exaggeration |

| A: Beginner | 1-2 days | £150-£350 | Basic knowledge | Awareness of concepts | “Master techniques” |

| B: Maintenance | 2-5 days | £350-£600 | Level 2 / experience | Methodology improvement | “Reduce downtime 50%” |

| C: Advanced | 5+ days | £600-£950 | Industrial experience | Specialist enhancement | “Expert in weeks” |

Additional costs often include travel, accommodation for multi-day courses, test equipment purchases if practicing independently post-course, and potential resit fees if practical exercises aren’t completed successfully first time. Factor these when comparing course prices.

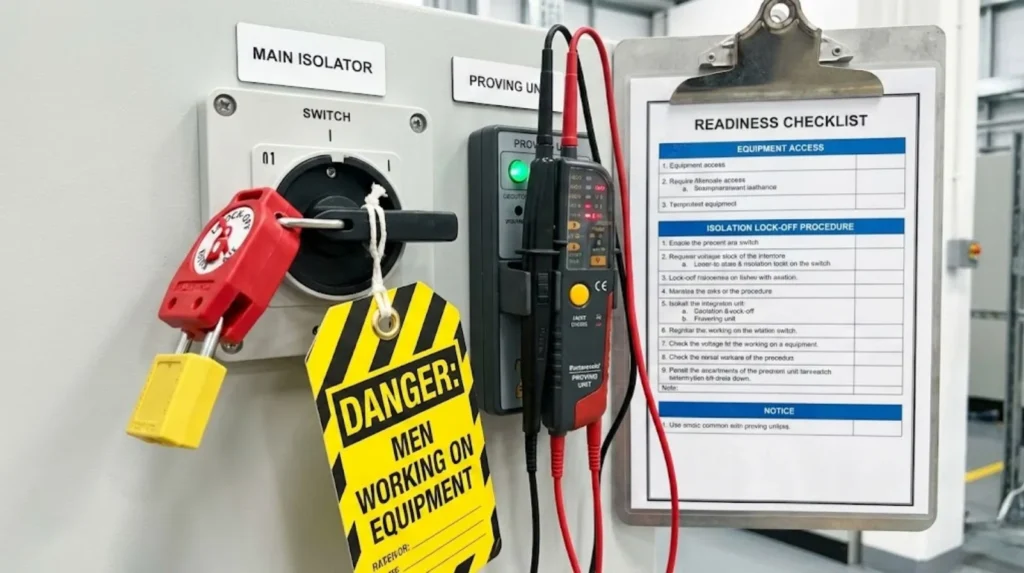

Before You Pay: Readiness Checklist

Save money and avoid disappointment by honestly assessing readiness before enrolling. These aren’t arbitrary barriers; they’re prerequisites determining whether courses deliver value.

Can you calculate expected circuit values? Fault-finding requires knowing what measurements should be, not just recording what they are. If you can’t calculate expected R1+R2 values for circuits or determine correct Zs thresholds from BS 7671 disconnection time requirements, you can’t identify whether test results indicate faults. The course won’t teach fundamental electrical theory; it assumes that knowledge exists.

Do you understand BS 7671 (18th Edition) requirements? Diagnostic work involves distinguishing between faults (system failures) and non-compliances (installations not meeting current standards). Without 18th Edition knowledge, you’ll misinterpret situations where installations function but don’t meet regulations. The fault-finding course focuses on diagnosis, not regulation interpretation.

Are you confident with safe isolation procedures? Fault diagnosis often involves testing near live conductors or confirming circuit de-energization. HSE guidance document GS38 specifies requirements for test equipment and procedures. The ten-step safe isolation sequence (identify circuit, isolate, lock off, prove dead, prove tester, re-prove dead, fit warning notices, etc.) must be automatic before attempting diagnostic work. Courses practice safe isolation but assume baseline competence; they’re not safe isolation training from scratch.

Do you have access to calibrated test equipment? Multifunction testers require annual calibration to HSE standards. Practicing diagnostic procedures on courses using training center equipment doesn’t translate to independent work unless you own or have access to properly calibrated instruments. Test results from uncalibrated equipment aren’t legally valid, regardless of correct procedures.

Have you confirmed supervision and insurance arrangements? Completing a fault-finding course doesn’t authorize independent electrical work. Legal competence under Electricity at Work Regulations requires knowledge, skills, and experience. Insurance for electrical work demands declared qualifications; attendance certificates don’t satisfy insurer competence requirements. If you’re employed, confirm your employer accepts responsibility for work undertaken. If self-employed, verify your public liability insurance covers diagnostic work at your actual qualification level, not aspirational level post-course.

Can you read electrical schematics and wiring diagrams? Industrial and commercial fault-finding requires interpreting technical drawings showing circuit layouts, control logic, and system integration. Domestic work involves understanding conventional wiring practices even when drawings don’t exist. If circuit diagrams look like abstract art rather than logical representations, diagnostic courses will overwhelm you regardless of instructor quality.

Who These Courses Actually Help (And Who They Don't)

Different learner groups gain different value from fault-finding courses. Honest matching prevents wasted investment.

Level 2 Diploma Students: Limited benefit. You’re still building foundational knowledge. Fault-finding courses assume understanding of circuit operation, protection devices, and testing principles. The course might provide motivational context showing how theory applies practically, but it’s premature for skill development. Better investment: focus on completing Level 3 before considering specialist courses.

Level 3 Diploma Completers / NVQ Learners: Moderate to high benefit. You have theoretical knowledge and are gathering workplace evidence for NVQ portfolios. Fault-finding courses provide structured practice preparing for AM2 Section C assessment and help develop systematic diagnostic approaches useful during site placements. Ensure courses specifically mention AM2 preparation if that’s your goal. Biggest risk: learning shortcut approaches rather than logical methodology.

Maintenance Operatives in Facilities Roles: High benefit if already employed and working under supervision. Courses improve repair efficiency and diagnostic confidence. Ensure your employer authorizes attendance and accepts responsibility for your work scope. Biggest risk: attempting work beyond actual competence level because course increased confidence without proportional experience increase. Legal liability remains with the person performing work, not the course provider.

Qualified Electricians (NVQ Level 3 + Gold Card): Very high benefit, minimal risk. You have formal competence foundations. Specialist fault-finding courses in areas like industrial controls, three-phase systems, or BMS integration add genuine capabilities within your existing credential framework. These are true continuing professional development activities. Focus on courses teaching systems or contexts unfamiliar to you rather than reinforcing existing skills.

Career Changers Without Electrical Background: Minimal benefit, high risk. Fault-finding courses aren’t entry routes into electrical work. They’re skill refinements for people already operating in the industry. Without Level 2 minimum knowledge and site experience, courses overwhelm learners and create dangerous overconfidence. Better path: pursue formal qualifications through apprenticeships or structured Level 2/3 routes before considering specialist courses.

Overseas Electricians Adapting to UK Standards: Moderate benefit. If you hold equivalent qualifications from other countries and need to understand UK-specific BS 7671 requirements and testing procedures, courses provide practical exposure to UK methods. Combine with 18th Edition certification and consider Experienced Worker Assessment routes for formal UK credential recognition. Courses alone don’t convert overseas qualifications into UK site access authorization.

Scotland vs England, Wales & Northern Ireland

Scotland’s electrical industry operates under SJIB (Scottish Joint Industry Board) governance rather than JIB, and uses SVQ (Scottish Vocational Qualification) terminology instead of NVQ. However, fault-finding course markets and expectations remain functionally identical.

Card schemes: SJIB/ECS cards in Scotland serve the same purpose as JIB/ECS cards elsewhere, providing site access and competence verification. Grading structures differ slightly in terminology but align in practice. Installation Electrician and Maintenance Electrician grades require equivalent competence demonstrations regardless of location.

Qualification routes: SVQ Level 3 in Electrotechnical Systems and Equipment (Scotland) parallels NVQ Level 3 in England, Wales, and Northern Ireland. AM2 assessment requirements apply across all UK regions. The competence evidence expected in SVQ portfolios matches NVQ requirements: workplace observations, photographic evidence, assessor witness statements.

Training providers: Scottish training centers offering fault-finding courses use the same tier structure and similar pricing to providers elsewhere. Course content reflects BS 7671 standards applying throughout the UK, though Scottish providers emphasize SJIB pathways and SELECT registration (Scotland’s electrical industry trade body) rather than NICEIC/NAPIT schemes more common in England.

Stricter pathways: Scotland maintains tighter control over crediting electrotechnical competence for workers without formal apprenticeships. The SJIB’s crediting processes scrutinize experience claims more rigorously than some JIB processes in other regions. This means fault-finding courses are even less likely to substitute for formal qualifications in Scottish contexts where pathway compliance receives closer examination.

Practical impact for fault-finding courses: none. Whether you’re in Glasgow, Cardiff, Birmingham, or Belfast, short courses provide skills practice but don’t create formal qualifications. Regional card scheme differences don’t change the fundamental reality that NVQ/SVQ Level 3 and AM2 are non-negotiable for qualified electrician status.

Misleading Claims and Red-Flag Language

Learn to spot problematic marketing before spending money. These phrases indicate providers overstating course value or misrepresenting outcomes.

Red Flag: “Become a qualified electrician in days” or “Fast-track to fault-finding expert”

Reality check: Qualified electrician status requires NVQ Level 3, AM2 assessment, and Gold Card. This pathway takes 18 months to 4 years depending on route. Expertise develops over years of varied site experience. No course condenses formal qualifications into days or weeks.

Red Flag: “Guaranteed employment” or “Earn £50,000/year as a fault-finding specialist”

Reality check: Employment depends on holding industry-recognized qualifications (NVQ/Gold Card), not course certificates. Earnings reflect JIB grading, regional markets, overtime availability, and experience levels. Course completion guarantees nothing regarding employment or salary.

Red Flag: “Fully qualified and certified fault-finder”

Reality check: There’s no such qualification as “certified fault-finder” in UK electrical industry. The only recognized credentials are NVQ Level 3, AM2, and associated specialist qualifications like 2391 Inspection & Testing. Certificates of attendance are not industry qualifications.

Red Flag: “No experience required” for maintenance or advanced courses

Reality check: Effective fault diagnosis requires foundational knowledge interpreting circuit behavior, using test equipment safely, and understanding electrical theory. Courses claiming beginners can gain competence in days ignore legal requirements for demonstrated competence under Electricity at Work Regulations.

Red Flag: “Work commercially after this course”

Reality check: Commercial electrical work on managed sites requires ECS Gold Card proving NVQ Level 3 and AM2 completion. Short courses don’t satisfy site access requirements. Attempting commercial work without proper credentials violates site regulations and insurance conditions.

Safe Language (What Compliant Providers Say):

“Develop diagnostic skills for qualified electricians”

“Practical preparation for AM2 Section C”

“CPD activity for maintenance electricians”

“Attendance certificate provided” (not “qualification achieved”)

“Supports progression toward NVQ evidence” (not “replaces formal qualifications”)

Check provider websites for specific claims about employment outcomes, earnings potential, or qualification status. If they’re overstating course value, that behavior extends to other aspects of service quality. Legitimate providers clearly distinguish between skills training and formal qualification pathways.

Practical Guidance: Making Informed Decisions

If you’re considering fault-finding courses after reviewing the distinction between skills training and formal qualifications, ask providers these specific questions before enrolling:

Does this course contribute evidence toward NVQ portfolios? If the answer is yes, ask for specifics about which units and what documentation is provided. Most courses don’t provide assessor-witnessed evidence acceptable for NVQ purposes despite claims of supporting qualification progress.

What prerequisite knowledge is genuinely required? Providers saying “basic electrical awareness” often mean Level 3 knowledge minimum. Ask what specific concepts (Ohm’s Law, circuit protection, earth fault loops) you should understand beforehand. If you don’t hold Level 2 minimum, you’re likely not ready regardless of what marketing materials suggest.

What happens after course completion? Clarify whether certificates have expiry dates, whether refresher training is recommended, and what authorization (if any) the certificate provides for independent work. Legitimate providers state clearly that courses don’t authorize unsupervised electrical work without proper underlying qualifications.

What is your refund policy? Consumer law requires distance sellers to allow 14-day cancellation rights, but in-person courses may have different terms. Understand cancellation policies before paying, particularly for expensive multi-day courses requiring travel commitments.

Can you provide references from employers who accept your certificates? If courses claim to improve employability, providers should demonstrate employers recognize their training. Request examples of companies hiring based on course completion. Inability to provide specifics suggests overstated employment claims.

For those pursuing electrician courses uk through proper qualification pathways, fault-finding skills develop naturally through NVQ evidence gathering and AM2 preparation. Short courses might accelerate specific aspects, but they’re supplements to formal training, not substitutes. The investment delivering genuine employability credentials remains NVQ Level 3, AM2 completion, and Gold Card acquisition.

Fault-finding courses provide practice environments, instructor demonstrations, and exposure to systematic diagnostic methodologies. They don’t create legal competence for independent electrical work, and they don’t substitute for formal qualification pathways. These are skill-building activities for people already operating within the electrical industry under appropriate supervision or holding proper credentials.

The competence required for safe, legal fault diagnosis comes from three sources working together: knowledge (understanding electrical principles, BS 7671 requirements, safe procedures), skills (correctly using test equipment, following diagnostic logic, implementing safe solutions), and experience (repeated exposure to varied fault conditions across different installation types). Courses provide some knowledge and limited skills practice. They cannot provide the experience component or the formal assessment proving you’ve achieved competence.

Before investing in fault-finding training, verify you meet prerequisites honestly: Can you read schematics? Do you understand BS 7671? Are you confident with safe isolation? Do you have access to calibrated equipment? Does your insurance or employer authorization cover the work you’ll attempt post-course? If answers are no or uncertain, address those foundations first through proper qualification routes.

For people holding NVQ Level 3 and seeking to develop specialist diagnostic skills in unfamiliar areas, fault-finding courses deliver genuine value as continuing professional development. For improvers, NVQ learners, or career changers, courses might help prepare for formal assessments, but they don’t replace the assessment requirements themselves.

The UK electrical industry recognizes NVQ Level 3, AM2, and ECS Gold Card status. It doesn’t recognize fault-finding course certificates as qualification equivalents. Employers specify Gold Card requirements in job descriptions; insurers require declared NVQ-level competence for liability coverage; sites check card status electronically at entry gates. No amount of short-course attendance changes these industry standards.

Make training investments that advance your formal qualification status. If you’re not yet qualified, focus on Level 2 and 3 diplomas, NVQ portfolio completion, and AM2 preparation. If you’re already qualified, target specialist courses developing capabilities in industrial controls, three-phase systems, or other advanced areas extending your existing competence. Don’t spend money on courses marketed as shortcuts to qualifications or employment. Those shortcuts don’t exist within legitimate electrical industry pathways.

For comprehensive information about professional electrician course pathways that deliver actual NVQ Level 3 credentials, AM2 preparation, and Gold Card eligibility, contact Elec Training on 0330 822 5337. We’ll explain exactly what formal qualifications require, realistic timelines, and how proper training differs from short courses sold as qualification substitutes. No misleading claims. No dangerous oversimplifications. Just factual guidance about routes that genuinely qualify people for electrical careers in the UK.

References

- HSE Guidance GS38 – Electrical Test Equipment for Use by Electricians: https://www.hse.gov.uk/pubns/books/gs38.htm

- Electricity at Work Regulations 1989: https://www.hse.gov.uk/electricity/

- BS 7671:2018+A2:2022 IET Wiring Regulations: https://electrical.theiet.org

- City & Guilds 2365 Level 2 and Level 3 Diplomas: https://www.cityandguilds.com

- City & Guilds 2357 NVQ Level 3 Electrotechnical Technology: https://www.cityandguilds.com

- City & Guilds 2391-52 Inspection and Testing: https://www.cityandguilds.com

- ECS Card Scheme Requirements: https://www.ecscard.org.uk

- JIB (Joint Industry Board) Handbook 2025: https://www.jib.org.uk

- SJIB (Scottish Joint Industry Board): https://www.sjib.org.uk

- NET Services – AM2/AM2E/AM2S Assessment: https://www.netservices.org.uk

- BSA Training – Electrical Fault Finding Course Information: https://www.bsatraining.co.uk

- Make UK – Industrial Electrical Fault Finding: https://www.makeuk.org

- Technical Training Solutions – Electrical Problem Solving: https://technicaltrainingsolutions.co.uk

Note on Accuracy and Updates

Last reviewed: 25 December 2025. This article reflects current UK electrical industry standards, HSE safety requirements, and qualification pathways as of December 2025. Course pricing represents 2025 market rates and may vary by provider and region. We update content as regulations, standards, and industry practices evolve. This is educational information only and does not constitute legal or professional advice regarding electrical work authorization.