Solar Panel Recycling: Is It the Next Big Opportunity for UK Electricians?

- Technical review: Thomas Jevons (Head of Training, 20+ years)

- Employability review: Joshua Jarvis (Placement Manager)

- Editorial review: Jessica Gilbert (Marketing Editorial Team)

- Last reviewed:

- Changes: Initial publication analysing UK solar waste projections and electrician opportunities

You’ve probably seen the headlines. “Solar panels will create a waste crisis.” “Millions of toxic panels heading to landfill.” “The dark side of green energy.”

Here’s what those headlines don’t tell you: the UK’s solar waste “crisis” is almost entirely a future problem, not a current one. Most UK solar installations happened after 2010. With 25–30 year lifespans, mass decommissioning won’t hit until the mid-2030s to 2040s.

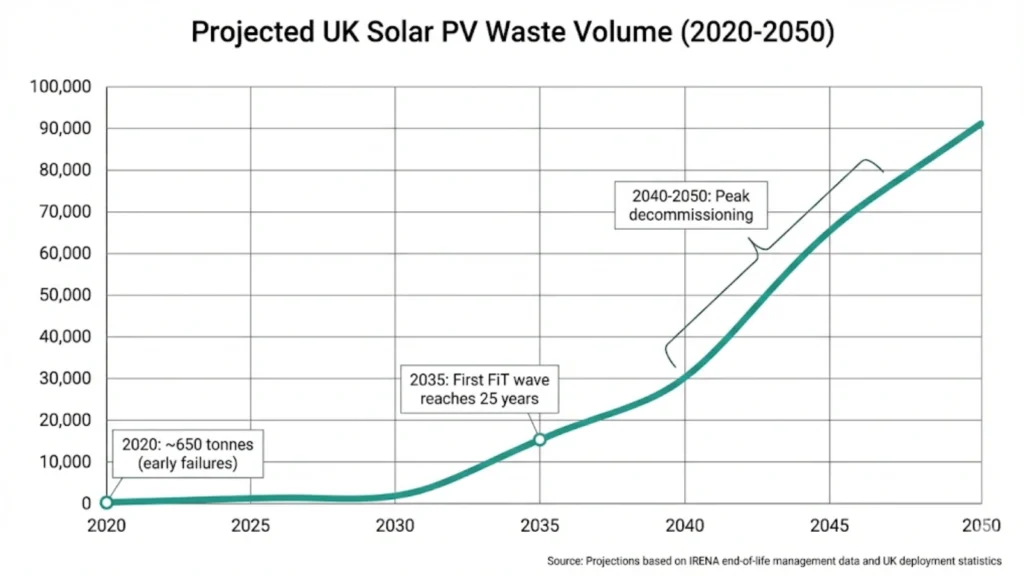

Right now, we’re in what industry analysts call the “lag phase.” Current waste volumes are minimal (around 650 tonnes in 2020), mostly from damaged panels and early upgrades, not genuine end-of-life removals. But by 2050, cumulative waste could exceed 2 million tonnes.

For electricians, the question isn’t “is there a crisis?” It’s “when does the work actually arrive, and what skills position you for it?”

What Actually Happens to Solar Panels at End-of-Life

Solar panels don’t suddenly stop working after 25 years. They degrade gradually at roughly 0.5% per year under UK conditions. After 25 years, most panels still produce around 80% of their original output. That’s degradation, not failure.

When panels do leave roofs or fields, it happens for three main reasons:

Physical damage: Storm damage, impact from falling debris, or manufacturing defects cause early removal. This represents the bulk of current waste: “infant mortality” rather than genuine end-of-life.

Repowering: Commercial sites replace older panels with newer, more efficient models before the originals fail. A 2010-era panel producing 250W might get swapped for a 2025 model producing 450W. Economically sensible for the site owner, but it accelerates waste generation.

Genuine end-of-life: The panel reaches 25-30 years, output has dropped below viable levels, and replacement makes economic sense. This is what we’re not seeing much of yet because most UK installations are too young.

Under UK WEEE (Waste Electrical and Electronic Equipment) regulations, solar panels cannot legally go to landfill. They must be collected, transported by licensed carriers, and processed at Authorized Treatment Facilities (ATFs). That’s not optional. It’s law.

Current recycling facilities in the UK (like Recycle Solar in Scunthorpe) can mechanically recover 90-95% of a panel by weight. Glass and aluminium frame (which make up about 75% of panel mass) are straightforward. Copper wiring is valuable. The silicon cells and trace metals like silver are technically recoverable but economically challenging at current waste volumes.

The Timeline: When Does This Actually Matter?

The UK’s Feed-in Tariff scheme drove a solar boom between 2010-2015. Those installations represent the first major wave heading toward end-of-life. Simple maths: 2010 + 25 years = 2035. 2015 + 25 years = 2040.

We’re currently in February 2026. That means the bulk of decommissioning work sits 9-14 years into the future.

Current UK solar capacity sits at approximately 19GW. Industry projections suggest cumulative waste exceeding 100 million modules (around 2 million tonnes) by 2050. But that’s cumulative. The year-on-year volumes build gradually through the 2030s before accelerating in the 2040s.

What about repowering? This could accelerate timelines by 5-10 years for commercial installations where efficiency gains justify early replacement. Solar farms installed in 2012-2015 might get repowered around 2027-2032 as panel efficiency improvements reach the point where replacement pays back within 5-7 years.

For electricians, this creates two distinct opportunity windows:

2026-2035: Early repowering work on commercial sites, plus ongoing maintenance and fault diagnosis on aging systems. Work exists now, but volumes are modest.

2035-2050: Mass decommissioning as the Feed-in Tariff installations reach genuine end-of-life. This is when volumes scale dramatically and sustained work opportunities arrive.

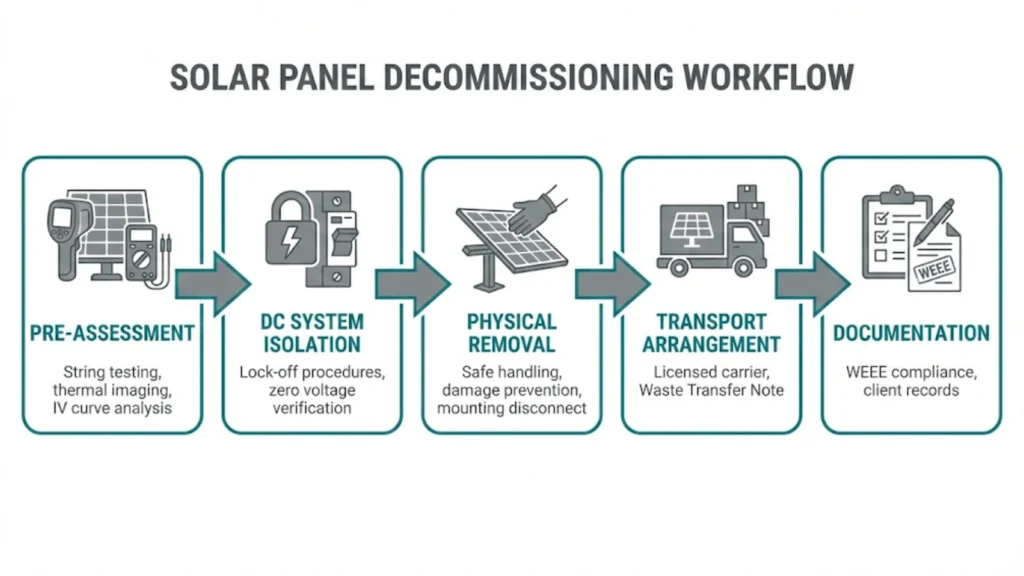

Understanding electrical diagnostic testing skills becomes crucial during the pre-decommissioning phase, as determining whether panels need removing or just maintenance requires competence in string testing, thermal imaging, and system performance analysis.

What Electricians Actually Do With Solar Decommissioning

There’s a persistent misconception that electricians will become “solar recyclers,” learning chemical processes and material recovery techniques. That’s not how the supply chain works.

Electricians handle decommissioning: safe removal of panels from sites. This involves DC isolation, disconnection from inverters, physical removal from mounting structures, and transport arrangements to authorized facilities. It’s skilled electrical work, not materials processing.

Recycling happens at specialist facilities by companies with the equipment and permits for materials recovery. Producer responsibility schemes (funded by panel manufacturers and importers) cover these costs for household installations. Commercial installations typically negotiate end-of-life costs in supply contracts.

The electrician’s role breaks down into specific competencies:

Pre-removal assessment: Before panels come down, determine if they’re genuinely end-of-life or just underperforming. String testing identifies broken connections. Thermal imaging spots hotspots from cell damage. IV curve analysis measures actual vs expected output. Often, what looks like panel failure is actually inverter issues, shading problems, or simple soiling.

Safe DC isolation: Solar panels generate voltage whenever light hits them. You can’t just “switch them off” like AC circuits. Proper isolation requires understanding DC system architecture, using appropriate lockout procedures, and verifying zero voltage before physical work begins. BS 7671 doesn’t comprehensively cover DC systems, so you’re working to MCS standards and manufacturer guidelines.

Physical removal without damage: Intact panels retain some recycling value. Broken glass contaminates other recyclable materials and increases disposal costs. Proper handling during removal (supporting panel weight correctly, avoiding stress on frames, protecting glass surfaces) matters economically and practically.

Waste Transfer Notes and compliance: Under WEEE regulations, electricians removing panels must document where they’re going. A Waste Transfer Note proves panels reached an authorized facility. Failure to provide this creates legal liability. It’s not optional paperwork, it’s regulatory compliance.

"Before panels come down, you need to assess whether they're genuinely end-of-life or just underperforming due to soiling, shading, or inverter issues. String testing, thermal imaging, and IV curve analysis determine if a system needs decommissioning or just maintenance. That diagnostic work is where the actual skill requirement sits."

Thomas Jevons, Head of Training

The skill isn’t in recycling. It’s in safe, compliant removal that preserves material value and meets regulatory requirements. That’s electrician work, not materials scientist work.

The Economics: Is There Actually Money in This?

Current decommissioning work pays standard electrician rates. You’re not commanding premium specialist rates for removing solar panels. Commercial rates typically sit around £25-35/hour employed, £40-50/hour self-employed depending on region and job complexity.

The opportunity isn’t in premium pricing. It’s in volume. As installations age, the work becomes more consistent rather than more lucrative per job.

For context on current volumes: In 2020, the UK generated approximately 650 tonnes of solar panel waste. At an average panel weight of 18-20kg, that’s roughly 32,500-36,000 panels annually. Spread across the entire UK, that’s not generating sustained work for specialist decommissioning teams.

By 2035, annual volumes could hit 20,000-30,000 tonnes, that’s over a million panels per year. By 2045, potentially 80,000-100,000 tonnes annually. At those volumes, decommissioning becomes a genuine workstream rather than occasional jobs.

Repowering offers nearer-term opportunities. Commercial solar farms installed in 2012-2015 might repower in the late 2020s to early 2030s. Each repowering project involves removing old panels, updating mounting structures, installing new higher-efficiency panels, and reconfiguring electrical systems. That’s weeks or months of work per site, not single-day removals.

The business case for electricians isn’t “specialize exclusively in solar decommissioning.” It’s “build renewable installation and maintenance competence, then add decommissioning as installations you worked on years ago reach end-of-life.” The work follows naturally from broader solar PV skills.

For those considering entering electrical training with an eye on renewable sectors, understanding part-time training options helps balance current employment while building qualifications for when solar decommissioning volumes scale up in the 2030s.

Who This Actually Benefits (And When)

The timing question matters enormously for career planning. If you’re considering electrical training now, when will solar decommissioning work actually be available?

For school leavers (16-19 years old) starting training in 2026:

You’ll complete your NVQ and qualify by 2029-2030. You’ll spend the early 2030s building experience on new installations and maintenance work. By 2035-2040 when decommissioning volumes scale up, you’ll be a 10-15 year experienced electrician in your early-to-mid 30s. That’s perfect positioning. You’ve got the skills, the experience, and you’re hitting peak earning years precisely when demand spikes.

For career changers (25-35 years old) starting training in 2026:

You’ll qualify by 2028-2030. The next 5-8 years you’re building renewable installation competence and establishing yourself in the sector. By 2035 when major decommissioning starts, you’re 35-45 years old with solid experience. You’re not too late, you’re ideally positioned as an experienced professional when volumes justify sustained work.

For established electricians (35-50 years old) in 2026:

If you’re already qualified but haven’t worked on solar, adding PV installation competence now sets you up for decommissioning work you can perform through your 40s and 50s. The work arrives in your later career years, potentially extending your active working life in a growing sector.

"For someone starting electrical training now at 25-30 years old, they'll be 35-40 when the UK's solar decommissioning work scales up properly in the mid-2030s. That's not too late, that's perfect timing. You spend the next decade building core electrical competence and renewable installation experience, then you're positioned as an experienced electrician when the volume work arrives."

Joshua Jarvis, Placement Manager

The pattern is consistent: people entering training now won’t be “too late” for solar decommissioning. They’ll be perfectly positioned as the work scales. The crisis narrative suggests urgency, but the timeline reality suggests strategic career building.

What Training Actually Prepares You

There are no specialist “solar panel recycling” qualifications for electricians because recycling isn’t the electrician’s role. What you need is standard renewable energy electrical competence plus WEEE awareness.

Foundation qualifications:

NVQ Level 3 (2357) proves core electrical competence. You can’t work on solar systems without understanding AC/DC systems, isolation procedures, and testing principles. This isn’t solar-specific, it’s fundamental electrical knowledge.

18th Edition (BS 7671:2018+A2:2022) covers UK wiring regulations. While BS 7671 doesn’t comprehensively address DC systems, it establishes the safety principles and testing methodologies you apply to solar work.

Renewable-specific additions:

City & Guilds 2919 (Solar PV Installation) covers system design, installation procedures, MCS standards, and grid connection requirements (G99). This teaches you how to install systems correctly, which informs how to remove them safely.

Inspection and Testing (2391) provides advanced diagnostic skills applicable to solar fault-finding. String testing, insulation resistance on DC circuits, and verification procedures all apply to pre-decommissioning assessment.

Compliance knowledge:

WEEE regulations training (often a short course or part of broader waste management CPD) covers legal requirements for waste documentation, licensed carrier selection, and Authorized Treatment Facility verification.

The training pathway isn’t “learn solar recycling.” It’s “become a competent electrician with renewable energy specialization, then understand the compliance requirements when systems reach end-of-life.”

Learning through hands-on training approaches proves particularly valuable for solar work, as understanding how systems install and commission directly informs how to diagnose faults and safely decommission them years later.

The Myths vs The Reality

Media coverage of solar waste often misrepresents timelines, volumes, and responsibilities. Here’s what actually matters:

Myth: Solar panels can’t be recycled and will overwhelm landfills

Reality: It’s illegal to send solar panels to UK landfill under WEEE regulations. Current facilities recover 90-95% of materials by weight. The infrastructure needs scaling for future volumes, but the technical capability exists and regulations mandate compliance.

Myth: Solar waste is already a huge problem

Reality: Current UK waste sits around 650 tonnes annually, that’s roughly 32,000 panels in a country with over 1 million installations. The volumes are minimal because most panels are under 15 years old. The “problem” arrives in 10-15 years, not now.

Myth: Electricians will need to become materials scientists

Reality: Electricians remove panels safely and document their disposal correctly. Materials recovery happens at specialist facilities. The skill requirement is electrical competence plus compliance awareness, not chemical engineering knowledge.

Myth: This undermines the environmental case for solar

Reality: Even accounting for end-of-life disposal, solar panels deliver net positive environmental benefits. A panel’s carbon payback period is 1-3 years. Over a 25-30 year lifespan, it generates far more clean energy than the carbon cost of manufacture and disposal. Recycling improves circularity but doesn’t change the fundamental climate benefits.

Myth: You need to specialize now to capture this opportunity

Reality: The work scales in the 2030s-2040s. Building broad electrical competence with renewable specialization positions you better than narrowly focusing on decommissioning that isn’t happening at volume yet. The diagnostic and installation skills you build now apply directly to decommissioning later.

The narrative of crisis and urgency benefits training providers selling expensive specialist courses. The reality is strategic: build solid renewable electrical competence now, add decommissioning as the work arrives.

What to Do If You're Considering This Route

If solar decommissioning interests you as part of broader renewable electrical work, here’s the practical pathway:

Start with core electrical qualifications

NVQ Level 3 (2357) provides your foundation. Without this, you can’t legally work on electrical systems, solar or otherwise. This takes 18 months to 3 years depending on your route (apprenticeship vs adult learner pathway).

Cost for full NVQ package at Elec Training: £10,500 including AM2 fee and PPE.

Add renewable specialization

City & Guilds 2919 (Solar PV Installation) or equivalent renewable energy qualifications demonstrate competence beyond standard electrical work. This differentiates you for solar installation and maintenance jobs that later extend into decommissioning.

Additional cost: £1,500-£2,500 typically for solar PV courses.

Build experience on installations and maintenance

The next 5-10 years, you’re working on new installations, fault-finding on existing systems, and performing maintenance work. This builds the diagnostic skills and system understanding that makes decommissioning straightforward when volumes scale.

Stay aware of WEEE compliance

As decommissioning work increases, understanding regulatory requirements matters. This isn’t a separate qualification, it’s professional awareness you build through CPD and industry updates.

Position for the 2030s volume increase

By the mid-2030s, you’re an experienced renewable electrician with 5-10+ years of solar work. When decommissioning volumes scale, you’re perfectly positioned because you understand how systems were installed, how they fail, and how to remove them safely.

What we’re not going to tell you:

- That you need to act urgently because the work is happening now (it isn’t at scale)

- That decommissioning will pay premium specialist rates (it pays electrician rates)

- That this replaces broader electrical competence (it supplements it)

What we will tell you:

- The work arrives in the 2030s-2040s, giving you time to build proper qualifications

- Core electrical competence plus renewable specialization positions you correctly

- Diagnostic skills and installation knowledge directly inform decommissioning work

- Career timing works well for people starting training in their 20s-30s now

Call us on 0330 822 5337 to discuss renewable energy training pathways and how solar PV competence fits into broader electrical career development. We’ll explain exactly what qualifications position you for the decommissioning work that scales up in the 2030s, realistic timelines from training to competence, and how our in-house recruitment team secures placements that build the installation and diagnostic experience you need. No hype about imminent crises. Just practical guidance on career timing that actually aligns with when the work arrives at volume.

FAQs

Is solar panel recycling currently a major problem in the UK?

No. Solar panel recycling is not currently a major issue in the UK because volumes of end-of-life panels remain low. Most panels installed during the early 2010s Feed-in Tariff boom carry 25–30-year warranties and are still operating.

Annual solar panel waste is estimated at under 1,000 tonnes, which is small compared with other forms of electronic waste. The Waste Electrical and Electronic Equipment Directive (WEEE) places responsibility on producers to fund collection and recycling, preventing uncontrolled disposal. Facilities such as PV Cycle UK currently handle volumes without capacity issues, and there is no evidence of landfill pressure or environmental harm.

When is large-scale solar panel decommissioning expected to begin in the UK?

Large-scale decommissioning is expected to begin in the 2030s, when panels installed between 2010 and 2015 approach the end of their warranted life.

Peak activity is forecast for the 2040s, particularly for utility-scale solar farms and domestic systems installed during the Feed-in Tariff era. Industry projections from bodies such as the Solar Trade Association suggest gradual increases from the late 2020s, but not a sudden or crisis-level surge.

What are the main reasons solar panels are removed before end-of-life?

Most early removals are driven by system upgrades, not failure. Owners may replace older panels with higher-output models to improve generation efficiency or adapt to new energy strategies.

Other reasons include:

- Storm or impact damage

- Roof repairs or structural alterations

- Building redevelopment or system relocation

Early decommissioning remains relatively uncommon compared with panels completing their full service life.

What work do electricians actually carry out during solar panel decommissioning?

Electricians are responsible for safe electrical isolation and system disconnection, not recycling itself. Typical tasks include:

- Assessing system condition

- Isolating DC and AC circuits

- Disconnecting inverters and cabling

- Dismantling mounting systems

- Preparing equipment for compliant WEEE collection

All work must comply with BS 7671, and panels must be correctly labelled and transferred to authorised waste handlers. Electricians do not process or recycle materials themselves.

How does solar panel decommissioning differ from standard PV installation work?

Decommissioning reverses the installation process but introduces additional risks. Instead of connection and commissioning, the focus is on:

- Safe isolation of aged systems

- Managing degraded components

- Preventing live DC hazards

- Completing WEEE documentation

Installation prioritises performance and integration, while decommissioning prioritises safety, verification, and disposal compliance. Both require strong PV system knowledge, but decommissioning adds end-of-life and environmental controls.

Does solar panel decommissioning pay more than standard electrical work?

At present, pay is broadly similar to standard electrical or renewable work. Typical day rates range from £200 to £400, depending on region and experience.

While specialist PV knowledge can attract a small premium, decommissioning volumes remain low, limiting earnings potential. Most electricians currently treat this work as part of broader renewables maintenance rather than a standalone income stream.

Which electricians are best positioned to benefit from solar decommissioning work?

Electricians with existing PV experience are best placed. This includes those:

- Certified under the Microgeneration Certification Scheme (MCS)

- Working with renewable energy contractors

- Operating in regions with high solar density, such as the South East

As decommissioning volumes increase in the 2030s, these electricians will be well positioned to absorb the work alongside installations and upgrades.

. What qualifications or skills prepare electricians for solar panel end-of-life work?

Key requirements include:

- Level 3 electrical qualification (e.g. City & Guilds)

- Current BS 7671 knowledge

- PV system competence (MCS Solar PV)

- DC systems and inverter familiarity

- Working-at-height safety training

- Risk assessment and method statement skills

Understanding WEEE obligations is also important, even though electricians are not responsible for recycling itself.

How do WEEE regulations affect electricians removing solar panels?

Under WEEE rules, removed panels are classed as electronic waste. Electricians must:

- Isolate systems safely

- Prevent damage during removal

- Ensure panels are transferred to authorised collectors

- Retain documentation where required

Recycling costs are covered by producers, not electricians. Failure to comply can result in enforcement action, so correct handling protects both the contractor and the client.

Should electricians specialise in solar panel recycling now or build broader renewable experience first?

For now, electricians should build broader renewable experience first. Solar decommissioning volumes will remain limited until the 2030s.

Expanding skills in areas such as:

- Solar PV installation and maintenance

- Battery storage

- Heat pumps

- EV charging

provides more consistent work and aligns with current net-zero demand. Specialising too early in recycling alone risks under-utilisation, whereas broad renewables competence creates flexibility as end-of-life work gradually increases.

References

- GOV.UK – Waste Electrical and Electronic Equipment (WEEE) Regulations – https://www.gov.uk/guidance/electrical-and-electronic-equipment-eee-producer-responsibility

- GOV.UK – Solar Photovoltaics Deployment Statistics – https://www.gov.uk/government/statistics/solar-photovoltaics-deployment

- IRENA – End-of-Life Management: Solar Photovoltaic Panels (2016) – https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_IEAPVPS_End-of-Life_Solar_PV_Panels_2016.pdf

- Ember Energy – UK Solar Generation Record Year 2024 – https://ember-energy.org/latest-insights/a-record-year-for-british-solar

- GreenMatch UK – Solar Panel Recycling Opportunities – https://www.greenmatch.co.uk/blog/2017/10/the-opportunities-of-solar-panel-recycling

- Waste Experts – Solar Panel Recycling UK – https://wasteexperts.co.uk/products-services/solar-panel-recycling

- ScienceDirect – Solar Panel Waste Management and Circular Economy – https://www.sciencedirect.com/science/article/pii/S0038092X24006807

- RatedPower – UK Circular Solar Industry – https://ratedpower.com/blog/UK-circular-solar-industry

- Renewable Energy Hub – Repowering vs Recycling Options – https://www.renewableenergyhub.co.uk/blog/repowering-vs-recycling-what-to-do-with-old-solar-panels

- HSE – Waste Management: Solar Panels – https://www.hse.gov.uk/waste/solar-panels.htm

Note on Accuracy and Updates

Last reviewed: 11 February 2026. This page is maintained; we correct errors and refresh sources as solar deployment data and WEEE regulations change. Waste projections cited are based on IRENA lifecycle analysis and UK government solar deployment statistics through 2025. Actual decommissioning timelines may vary with repowering patterns and early failures. Next review scheduled following 2026 Q4 solar deployment data release (January 2027).