What Employers Really Look for When Hiring Mates & Improvers (UK)

- Technical review: Thomas Jevons (Head of Training, 20+ years)

- Employability review: Joshua Jarvis (Placement Manager)

- Editorial review: Jessica Gilbert (Marketing Editorial Team)

- Last reviewed:

- Changes: New comprehensive article addressing employer hiring criteria for electrical mates and improvers in UK, covering role definitions (mate vs improver vs electrician), supervision requirements distinguishing roles, safety and reliability as primary screening factors, competence evidence versus qualification certificates, ECS card requirements for site access, behavioral signals employers prioritize in first week, common rejection reasons (poor attendance, excessive supervision needs, safety breaches), job advert language interpretation, sector-specific expectations, myths about partial qualifications guaranteeing employment, tool ownership as commitment indicator, hidden market hiring through networks, and realistic assessment framework based on employer risk minimization and productivity logic

Electrical contractors hiring mates and improvers operate under different decision framework than training providers issuing qualifications. Understanding this distinction prevents costly misunderstandings about employability versus certification.

Employers minimize two primary risks: safety liability under Health and Safety Executive Electricity at Work Regulations requiring workers possess adequate competence or supervision, and productivity drain where supervision burden exceeds worker contribution. Candidates reducing these risks get hired. Candidates increasing these risks get rejected regardless of qualification level.

The fundamental employer question for mates: “Will this person increase or decrease my lead electrician’s productivity?” A productive mate anticipates needs, organizes materials, handles logistics, allows qualified electrician to focus on technical work. A problematic mate requires constant instruction, creates additional work, turns productive tradesperson into babysitter.

For improvers, the question shifts: “Can this person complete defined circuits or installations with minimal periodic oversight, contributing measurably to team output?” Improvers must work within task-based supervision (briefed on requirements, execute independently, work inspected before closing up) rather than requiring constant direct oversight.

This productivity and risk logic explains why employers sometimes prefer candidates with minimal qualifications plus 6 months basic site experience over diploma-holders with zero site hours. Site-experienced candidates already understand construction culture, safety expectations, team dynamics, site protocols. Diploma-only candidates represent unknown behavioral risk requiring extensive cultural onboarding beyond technical capability assessment.

Critical distinction: What makes mates or improvers employable differs fundamentally from what makes them qualified. Qualifications (Level 2/3 diplomas) signal theoretical knowledge and workshop capability. Employability requires demonstrated competence under real working conditions: reliability, safety compliance, ability to follow instructions, appropriate supervision requirements for role, quality standards without excessive rework, professional behavior on sites.

Understanding the complete UK electrician qualification pathway from entry-level through NVQ Level 3 and qualified status provides context for where mates and improvers fit within broader career progression, but qualification stages don’t directly translate to immediate employability at each level without corresponding competence evidence.

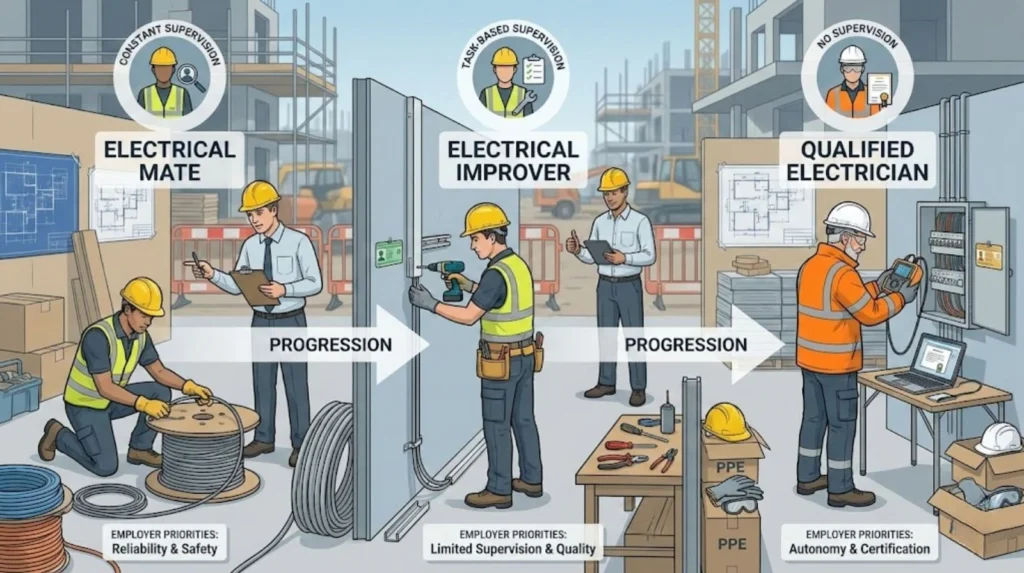

Defining Roles: Mate, Improver, Electrician

UK electrical industry lacks single universal definition for “mate” and “improver” roles. Terminology varies by employer, region, sector, contractor size. However, functional distinctions exist based on supervision requirements, task responsibility, and competence expectations.

Electrical Mate

Primary function: Supportive labor under constant direct supervision. Increases lead electrician’s productivity by handling logistics, material movement, basic preparation tasks.

Supervision level: Constant direct oversight. Works within eyesight of qualified electrician who checks every step before proceeding. Cannot work independently on any electrical tasks.

Typical responsibilities: Material handling (carrying cable drums, distribution boards, tools, equipment), cable pulling through installed containment, preparing work areas (clearing debris, protecting surfaces, organizing materials), assisting qualified electrician with installations (holding equipment, passing tools, supporting work), basic site tidying and cleanup, loading/unloading vans.

Task limitations: Does not perform electrical connections, terminations, or testing. Does not work on energized systems. Does not make technical decisions about installation methods or compliance.

Qualification signals: Often minimal or no electrical qualifications. May hold ECS Electrical Labourer card or be working toward basic Level 1/2 credentials. Previous construction labor experience valued over electrical-specific training.

Employer expectations: Punctuality, physical stamina, ability to follow instructions precisely without requiring repetition, safety awareness (appropriate PPE use, hazard recognition, following site protocols), initiative in supportive tasks (anticipating needs, organizing materials proactively), reliable attendance.

Pay range: Typically £10 to £14 per hour depending on region, experience, employer. London rates higher (£12 to £16 per hour). Reflects unsupervised labor value.

Thomas Jevons, our Head of Training, explains the critical distinction:

"The distinction between mate and improver isn't primarily about job title. It's about supervision burden. A mate requires constant direct oversight, working within eyesight of the qualified electrician who checks every step before proceeding. An improver should work with periodic task-based supervision, where the qualified electrician briefs the task, allows execution, then inspects the completed work before closing up. If someone holding Level 3 diplomas still requires constant instruction on basic installation procedures, they functionally operate as a mate regardless of qualification level. Supervision intensity determines role capability, not certificates alone."

Thomas Jevons, Head of Training

Electrical Improver

Primary function: Part-skilled installation work under limited periodic supervision. Capable of completing defined circuits or basic installations with task-based oversight.

Supervision level: Periodic task-based supervision. Qualified electrician briefs requirements, allows independent execution, inspects completed work before closing up or energizing. Does not require constant instruction for every step.

Typical responsibilities: First fix containment installation (cable tray, cable basket, steel conduit, plastic conduit systems), cable pulling and support, second fix wiring (socket circuits, lighting circuits under defined parameters), basic distribution board wiring under supervision, reading simple construction drawings and locating work accordingly, basic testing under qualified supervision, assisting with more complex installations.

Task limitations: Cannot work completely unsupervised. Cannot sign off electrical work or issue certificates. Cannot work on live systems without direct qualified oversight. Cannot make final compliance decisions. Requires qualified electrician inspection before energizing circuits.

Qualification signals: Typically holds Level 2/3 diplomas (C&G 2365-02, 2365-03) or equivalent. Working toward NVQ Level 3 through on-site evidence gathering. May hold 18th Edition Wiring Regulations certificate. Holds ECS Trainee card or equivalent demonstrating progression toward full qualification.

Employer expectations: Ability to work with limited oversight on defined tasks, quality workmanship requiring minimal rework, reading and interpreting construction drawings accurately, understanding of BS 7671 requirements for installations being performed, appropriate tool use and maintenance, contributing to team productivity rather than draining supervision time, accepting feedback and improving performance, safety awareness sufficient for semi-autonomous work within defined limits.

Pay range: Typically £12 to £18 per hour depending on region, competence level, NVQ progression. London rates £15 to £22 per hour. Some employers use JIB grading system linking pay to qualification milestones.

Critical employer assessment: Can this improver reduce qualified electrician’s workload by completing installations independently that only require final inspection, or do they still need step-by-step guidance making them functionally equivalent to mate despite holding qualifications?

Electrician (Qualified/Gold Card)

Primary function: Fully competent electrical work without supervision. Can design, install, commission, test, and certify electrical installations to BS 7671:2018+A2:2022.

Supervision level: None required for standard installations within scope of competence. Can supervise mates and improvers.

Qualification requirements: NVQ/SVQ Level 3 in Electrotechnical Technology, AM2/AM2E/AM2S practical assessment pass, 18th Edition Wiring Regulations, ECS Gold Card (or SJIB Approved Electrician in Scotland).

Pay range: Typically £18 to £28 per hour employed, higher for self-employed rates. London £22 to £35 per hour. Specialist roles (testing, industrial maintenance) potentially higher.

Relevance to mates/improvers: This is the target qualification level. Mates and improvers are progression roles building toward electrician status, not permanent career positions.

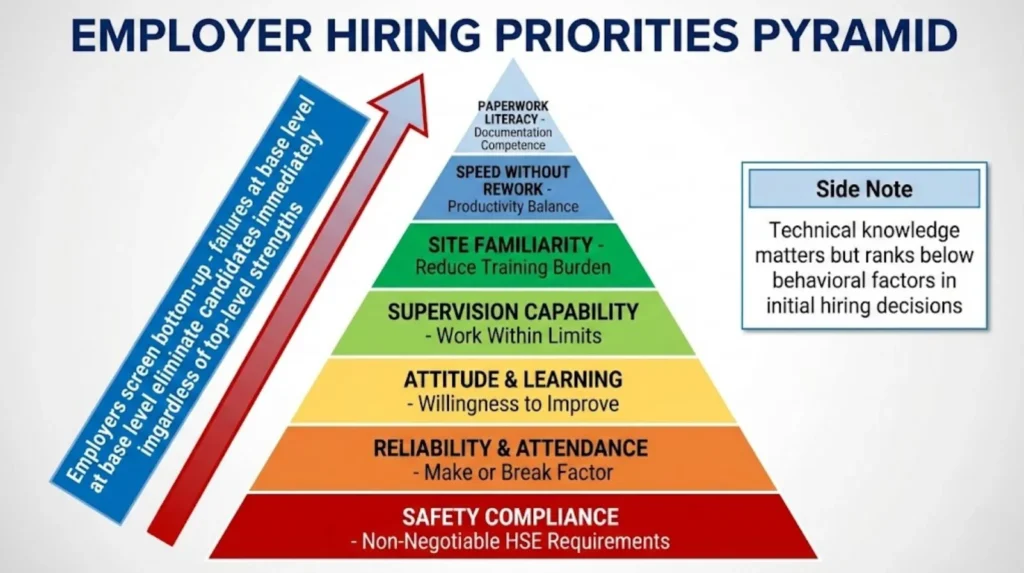

What Employers Actually Screen For

Employer hiring criteria ranked by priority based on risk minimization and productivity logic. Understanding this hierarchy explains rejection reasons and employment retention patterns.

1. Safety Compliance and Rule-Following (Non-Negotiable)

Health and Safety Executive Electricity at Work Regulations 1989 require employers ensure workers possess sufficient competence or receive adequate supervision to prevent danger from electrical work. Employers face legal liability for allowing unsafe work practices.

What employers assess:

Appropriate PPE use without reminders (hard hat, hi-vis, safety boots, gloves where required). Understanding of isolation procedures, lockout/tagout, and prohibition of working on live systems. Ability to follow Risk Assessment Method Statements (RAMS) and site-specific safety protocols. Hazard recognition and appropriate response (reporting, avoiding, seeking guidance). Following permit-to-work systems on controlled sites. Adherence to working at height regulations (harness use, scaffold safety, ladder protocols).

Why non-negotiable: Single safety breach can result in: immediate site removal by client, contractor losing site access or certification, HSE prosecution with unlimited fines, personal injury or fatality, insurance liability, reputation destruction ending business.

Common rejection signals: Not wearing PPE without being told. Working on circuits without confirming isolation. Ignoring safety barriers or exclusion zones. Dismissing RAMS as “paperwork” rather than essential compliance. Previous incidents or near-misses on other sites. Casual attitude toward height work or electrical hazards.

Employers will not compromise on safety compliance for any other candidate strength. Technical brilliance with poor safety awareness equals immediate rejection.

2. Reliability and Attendance (Make or Break Factor)

Construction sites operate on tight schedules coordinating multiple trades. Late arrivals or absences create cascading delays affecting entire project timeline.

What employers assess:

Punctuality for start time (typically 7am or 7:30am). Ideal: arrive 15 minutes early demonstrating commitment. Consistent attendance without unexplained absences or frequent sick days. Reliability with overtime requests or weekend work when project demands require. Communication about unavoidable absences (advance notice, legitimate reasons, not habitual pattern). Staying until agreed finish time rather than leaving early.

Why critical: Employers operate on small margins. Hourly wages continue regardless of productivity. Unreliable worker costs include: wasted supervision time, project delays, other trades waiting, client complaints, potential penalty clauses, difficulty planning work allocation.

Common rejection signals: Arriving late in first week (typically results in immediate dismissal or not invited back). Pattern of Monday absences or Friday early departures. Frequent vague illness claims. Giving minimal notice for absences. Unreliable about availability for necessary overtime.

Reality check: Arrive late once in probationary period, employment unlikely to continue. Reliability trumps technical knowledge initially. Employers forgive skill gaps much faster than attendance problems.

3. Attitude to Supervision and Learning

Willingness to accept instruction, implement feedback, admit knowledge gaps rather than pretending competence.

What employers assess:

Response to correction (implementing changes vs defensive arguing). Asking clarifying questions when instructions unclear rather than guessing. Admitting when unsure rather than risking mistakes from assumed knowledge. Initiative in improving after feedback rather than repeating same errors. Respect for qualified electrician’s experience and authority regardless of age differences. Willingness to perform unglamorous tasks (cleaning, organizing, material prep) without complaints.

Positive signals: “I haven’t done that before, can you show me?” demonstrates honesty and learning attitude. “I’ve finished this task, what should I do next?” shows initiative. Taking notes or photos of new procedures for reference. Checking work quality before calling supervisor for inspection.

Negative signals: “I know how to do this” followed by incorrect execution. Repeating same mistake after correction indicating not listening. Standing idle waiting to be told next task rather than asking. Defensive responses to feedback or blaming tools/materials. “Know-it-all” attitude particularly from candidates with recent qualifications but minimal site experience.

4. Ability to Work Within Supervision Limits (Improver Differentiator)

For improvers specifically, capability to execute tasks with periodic rather than constant supervision distinguishes them from mates.

What employers assess:

Completing straightforward installations (containment runs, socket circuits) after initial briefing without requiring step-by-step guidance. Quality consistency across repeated tasks showing learning and improvement. Reading construction drawings accurately and locating work without constant verification. Understanding task requirements from brief rather than needing every detail spelled out. Recognizing when guidance needed (complex situations, unfamiliar tasks) rather than either asking constantly or proceeding incorrectly.

Why decisive: If improver-titled candidate requires same supervision intensity as mate, employer questions value for higher wage. Improvers should reduce qualified electrician’s supervision burden, allowing them to focus on complex work, design, testing, client liaison. Improver needing constant oversight defeats hiring purpose.

Common rejection for improvers: Inability to work independently on basic tasks after demonstration. Requiring qualified electrician presence for every step of simple installations. Quality inconsistency requiring excessive rework. Lack of problem-solving when encountering routine obstacles.

5. Familiarity with Site Routines, Drawings, and Materials

Understanding construction site culture, document interpretation, material identification reduces training burden and error rate.

What employers assess:

Reading construction drawings sufficiently to locate work areas, understand floor plans, identify electrical layouts. Material recognition (differences between conduit types, cable specifications, fixing methods, accessories). Tool familiarity appropriate to role level. Understanding site terminology and communication protocols. Following site logistics (material deliveries, waste disposal, access routes, coordination with other trades).

Trainable gaps vs immediate expectations: Employers expect candidates to know basic material identification (what is conduit vs trunking vs basket), tool purposes, drawing conventions. Specific contractor procedures, particular material suppliers, site-specific logistics are trainable. Candidate unfamiliar with fundamental materials or unable to read simple drawings signals excessive training requirements.

6. Speed Without Rework

Productivity matters but quality takes precedence. Rework costs more than initial slower careful work.

What employers assess:

Task completion pace relative to role expectations (mates handling logistics efficiently, improvers completing installations at reasonable speed). Quality consistency requiring minimal correction or reinstallation. Accuracy in measurements and positioning. Proper techniques preventing damage to materials or existing structures.

Employer calculation: Slow careful work developing speed with experience is acceptable. Fast careless work requiring reinstallation, material replacement, correcting damage to building fabric costs significantly more. Single containment installation requiring complete removal and reinstallation potentially costs more than hiring worker for entire week.

Balance: Speed expectations increase with experience. New mates and improvers not expected to match experienced worker pace immediately. However, persistent slowness or quality issues preventing productivity contribution lead to performance reviews and potential dismissal.

7. Paperwork and RAMS Literacy

Compliance-heavy environments (commercial, industrial) require documentation competence.

What employers assess:

Ability to read and understand Risk Assessment Method Statements. Completing timesheets accurately. Recording materials used for job costing. Filling out handover documentation. Following permit-to-work procedures. Understanding test certificate requirements (for improvers progressing toward testing capability).

Why matters: Commercial sites with main contractors often require extensive documentation compliance. Workers unable to complete required paperwork create additional burden for qualified staff. Incorrect documentation can result in payment disputes, compliance failures, client complaints.

Common issue: Candidates treating paperwork as annoyance rather than essential compliance requirement. Errors in timesheets affecting payroll and job costing. Failure to complete induction documentation properly.

Qualifications, Cards, and Employment Signals

Understanding relationship between certification, site access requirements, and actual employment decisions prevents costly assumptions.

The Competence vs Qualification Distinction

Qualification evidence: Certificates from training providers (Level 2/3 diplomas C&G 2365, NVQ Level 3, 18th Edition) demonstrating attendance, assessment completion, theoretical knowledge, workshop practical capability under controlled conditions.

Competence evidence: Demonstrated practical skills under real working conditions, safe working behavior on actual sites, appropriate quality standards, ability to work within defined supervision levels, reliability and professionalism over time, problem-solving under commercial pressures.

Employer priority: Competence evidence significantly outweighs qualification evidence in hiring decisions. Qualifications help secure interviews (filtering function) but don’t guarantee employment. Competence evidence through references, site experience, work trials determines actual hiring.

Common learner error: Assuming Level 3 diploma automatically creates improver status and corresponding wages. Diploma signals theoretical knowledge and workshop capability. Employers assess whether candidate can perform under real site conditions with commercial time pressures, quality expectations, safety compliance, team dynamics.

The ECS Card Requirement

Electrotechnical Certification Scheme (ECS) provides competency cards enabling site access on controlled commercial and industrial projects. Card types relevant to mates and improvers:

ECS Electrical Labourer card: For supportive roles under supervision. Requires basic health and safety assessment, often no electrical qualifications. Signals to employers: basic site access capability, minimal technical responsibility expected.

ECS Trainee card: For learners progressing toward qualification. Requires enrollment in electrical training program, health and safety assessment. Signals: working toward Level 3, requires supervision, building NVQ evidence.

Why cards matter: Approximately 80 to 90% of commercial and industrial construction sites require ECS cards for electrical workers as insurance and compliance requirement. Without appropriate card, employers cannot physically allow site access regardless of capability. Card is permission gateway, not competence verification.

Card limitations: Holding ECS card doesn’t guarantee employment. Card proves minimum safety awareness and qualification enrollment. Employment depends on competence evidence, references, behavioral assessment, demonstrated productivity.

CSCS vs ECS confusion: Construction Skills Certification Scheme (CSCS) provides access to general construction sites for non-electrical trades. Some sites accept CSCS for electrical mates performing basic labor. However, electrical improvers and electricians typically require ECS specifically. Agencies and contractors interpret requirements variably. Safest approach: obtain appropriate ECS card for electrical progression.

Tool Ownership as Commitment Signal

Joshua Jarvis, our Placement Manager, explains employer assessment:

"When employers ask improver candidates about personal tool ownership, they're not primarily interested in tool inventory. They're assessing commitment signals. An improver turning up to interview with comprehensive personal toolkit including battery-powered tools, testing equipment, hand tools demonstrates: financial investment in electrical career, understanding of professional requirements, readiness for immediate productive contribution, serious intent beyond casual employment. Candidate arriving with minimal tools or borrowed kit signals: testing whether electrical work suits them, unwilling to invest until guaranteed outcome, potentially temporary commitment, higher risk of early departure. Tool ownership isn't requirement necessarily but it's powerful positive indicator employers notice."

Joshua Jarvis, Placement Manager

What employers infer from tool ownership:

Comprehensive personal toolkit (for improvers): Battery-powered drill, impact driver, SDS drill, multimeter, voltage tester, hand tools (screwdrivers, pliers, wire strippers, spanners), spirit level, tape measure, torch, cable strippers. Investment typically £500 to £2,000 depending on quality. Signals serious career commitment, understanding of professional requirements, readiness for immediate contribution.

Minimal tools or borrowed kit: Basic screwdriver set, borrowed or household-quality tools, no battery equipment. Signals testing career viability before investment, temporary commitment, higher risk of early departure, employer will need to provide tools reducing worker’s professional credibility.

Mate tool expectations: Lower than improvers. Basic hand tools sufficient initially. However, having own PPE (hard hat, boots, hi-vis, gloves) demonstrates readiness and reduces employer setup costs.

Reality: Tool ownership not absolute requirement (some employers provide site tools, particularly for mates). However, improvers with comprehensive toolkits consistently receive preference in hiring decisions over equivalent candidates without. Investment signals commitment employers value highly.

The “Paper Trap” for Diploma Holders

Candidates completing Level 2/3 diplomas sometimes believe qualification automatically elevates them to improver status and wages. Employer perspective differs significantly.

Diploma-holder without site experience: Viewed as “mate with a book.” Has theoretical knowledge but unproven practical capability, unknown behavior under commercial pressures, requires extensive cultural onboarding understanding construction site protocols, higher risk requiring significant supervision investment.

Mate with 6 months site experience, minimal qualifications: Already demonstrates reliable attendance, safety compliance, ability to follow instructions, understanding of construction culture, team dynamics, practical tool capability. Known quantity with proven reliability.

Employer preference: Often favor experienced mate over diploma-only candidate for improver positions. Can train technical gaps more easily than instilling reliability, safety awareness, professional behavior. Sites value behavioral predictability over theoretical knowledge when choosing between risk profiles.

Strategy for diploma-holders: Seek any site access opportunity (mate positions, laborer roles, temporary agency placements) to build competence evidence and references. Six months demonstrated reliability dramatically improves employability for improver positions versus applying immediately post-diploma completion.

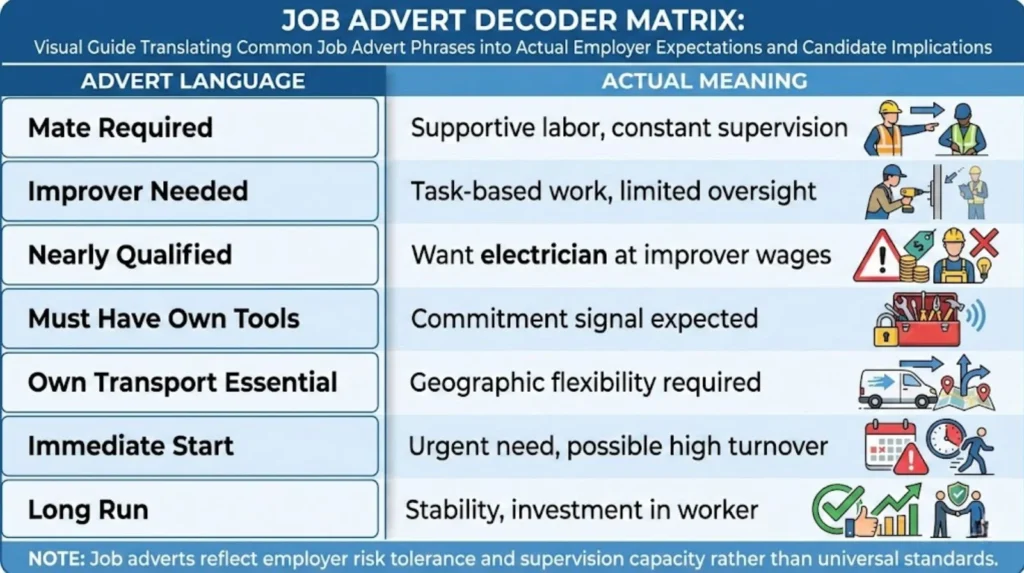

Job Advert Language Decoded

Understanding how employers communicate requirements and expectations through job advertisements reveals unwritten criteria and cultural signals.

“Mate Required”

Surface meaning: Entry-level supportive role.

Employer expectation: Constant supervision acceptable, primarily logistics and labor, minimal technical responsibility, focus on reliability and physical capability.

Red flags in advert: “Experience essential” signals employer has zero training capacity, wants someone who already understands construction site culture and behavior. “Immediate start” means urgent need, likely replacing someone dismissed for poor performance or attendance. “Long run of work” suggests stable opportunity but also expectation of commitment.

Who should apply: Candidates comfortable with supportive labor role, not expecting technical skill development, prioritizing employment stability over rapid progression.

“Improver Needed”

Surface meaning: Part-skilled role progressing toward qualification.

Employer expectation: Can complete basic installations with task-based supervision, holds Level 2/3 diplomas or working toward qualifications, reducing qualified electrician’s workload measurably, contributing to productivity not draining supervision time.

Red flags in advert: “Must be able to work alone” contradicts improver supervision requirements legally, signals employer lacks qualified supervision capacity or expects autonomous work inappropriate for improver. “Nearly qualified preferred” often means employer wants electrician capability at improver wages. “Own transport essential” suggests scattered sites or rural location requiring independence.

Who should apply: Candidates genuinely capable of task-based supervised work, holding relevant qualifications plus some site experience, understanding they’re not yet autonomous despite skills development.

“Nearly Qualified”

Surface meaning: Accepting candidates approaching full electrician status.

Employer expectation: Holds Level 3 diplomas plus significant site experience or completing NVQ final stages, can work with minimal supervision on most standard tasks, approaching AM2 assessment, understands still requires qualified oversight before energizing or certifying.

Reality check: Sometimes employers use this hoping for electrician-level performance at improver wages. Legitimate usage indicates employer has qualified supervision available and wants someone progressing rapidly toward full qualification who needs final NVQ evidence gathering opportunity.

Who should apply: Candidates genuinely in NVQ Level 3 final stages or with Level 3 qualifications plus substantial site experience, comfortable with supervised role despite advanced capability, clear on still requiring qualified oversight until AM2 completion.

“Must Have Own Tools”

Surface meaning: Candidate provides personal equipment.

Employer expectation: Professional commitment, readiness for immediate productivity, reduced employer setup costs, signals serious career intent rather than casual employment testing.

Implications: More common for improvers than mates. Suggests employer expects self-sufficiency and professional approach. Often indicates smaller contractor where sharing tools impractical. May signal sub-contractor relationship rather than direct employment (verify PAYE vs CIS tax implications).

Who should apply: Candidates with established tool investment (typically improvers), comfortable with professional responsibility, not expecting employer-provided equipment for all tasks.

“Own Transport Essential”

Surface meaning: Must reach site independently.

Employer expectation: Reliability not dependent on public transport schedules, flexibility for varying site locations, reduced employer logistics burden, often signals scattered sites or rural locations.

Reality: Small contractors particularly domestic-focused may work across wide geographic area. Expecting workers to meet at sites directly rather than workshop pickup. Candidates reliant on public transport face immediate disadvantage.

“Immediate Start” / “ASAP”

Surface meaning: Urgent hiring need.

Employer reality: Usually replacing worker dismissed for poor performance, attendance issues, or safety breaches. Alternatively, unexpected project demands or contract wins creating sudden capacity need. Time-sensitive work requiring someone ready from day one without onboarding delay.

Risk signals: Higher risk situation due to urgency potentially indicating problematic site culture (high turnover), desperate hiring reducing screening rigor (takes anyone available risking poor fit), immediate performance expectations without settling-in period.

Opportunity signals: Employer may be more willing to take chance on less experienced candidate due to urgent need, faster hiring process, immediate employment start.

“Long Run” / “Ongoing Work”

Surface meaning: Extended employment duration expected.

Employer expectation: Seeking reliable long-term worker, not short-term project fill, values consistency and relationship building, often indicates stable contractor with regular client base.

Positive indicator: Suggests employer invests in worker development, better working relationships possible, income stability, reduced job-search stress.

Sector Differences in Expectations

Employer priorities and working conditions vary substantially by sector affecting mate and improver experiences and progression opportunities.

Domestic Electrical Work

Typical employer profile: Sole traders, small firms (1 to 3 electricians), family businesses, self-employed contractors.

Mate/improver role characteristics: Close working with single qualified electrician, direct instruction and immediate feedback, customer-facing environment in occupied homes, need for professional behavior with clients, emphasis on tidiness and site cleanliness, varied work locations daily.

Card requirements: Often relaxed compared to commercial sites. Many domestic contractors operate without requiring ECS cards initially. However, progression to qualified status still requires ECS Gold Card for professional credibility.

Key skills emphasis: Customer communication and professionalism, working in confined spaces (lofts, underfloor, tight rooms), tidiness and cleanliness protecting client property, flexibility across varied domestic tasks, ability to work in occupied premises without disruption.

Progression pathway: Mate → Improver progression depends on single qualified electrician’s capacity to supervise NVQ evidence gathering. Smaller employers may struggle providing sufficient work diversity for complete NVQ portfolio. Benefits: Close mentorship relationship, varied work exposure, direct skill development. Challenges: Limited scale for rapid progression, dependent on single supervisor’s availability, potential income ceiling.

Common rejection reasons: Poor customer interaction skills, untidy work habits damaging reputation, inability to work respectfully in client homes, excessive chattiness or distraction, damage to client property through carelessness.

Commercial Fit-Out and New Build

Typical employer profile: Medium to large contractors (5 to 50+ electricians), project-based firms, main contractor subcontractors.

Mate/improver role characteristics: Team-based work, multiple qualified electricians on site, high-volume installations (extensive containment, cable pulling, first/second fix), emphasis on speed and productivity, less customer interaction (building occupants not usually present), standardized systems and repetitive tasks.

Card requirements: ECS cards typically mandatory. Main contractors enforce strict site access policies. HSE inductions required. CSCS or ECS essential for site entry.

Key skills emphasis: Speed and efficiency in repetitive tasks, ability to work in teams coordinating with other trades, reading construction drawings and locating work from plans, handling high-volume material movement, physical stamina for sustained manual work, compliance with main contractor health and safety regimes.

Progression pathway: Larger scale provides more opportunities for NVQ evidence diversity. Multiple qualified electricians potentially available for assessor coordination. However, high-pressure environment with tight deadlines. Benefits: Exposure to large-scale systems, team learning environment, potentially faster NVQ completion due to work volume. Challenges: Less individual mentorship, pressure for productivity over learning, temporary project-based employment affecting continuity.

Common rejection reasons: Inability to maintain required work pace, poor teamwork and communication with other trades, failure to follow main contractor site rules, quality issues causing delays to project schedule.

Industrial Maintenance and Manufacturing

Typical employer profile: In-house maintenance teams, specialist industrial contractors, plant maintenance providers.

Mate/improver role characteristics: Focus on heavy electrical systems (motors, control panels, distribution, machinery), working in operational facilities with live plant equipment nearby, strict permit-to-work and isolation procedures, shift patterns common (days, nights, weekends), emphasis on safety in high-risk environments, specialized equipment and systems.

Card requirements: ECS cards mandatory. Often additional site-specific safety certifications required. Enhanced background checks for sensitive facilities (pharmaceutical, defense, utilities). Strict adherence to permit systems.

Key skills emphasis: Rigid compliance with safety procedures, understanding of industrial systems and controls, ability to work in noisy and challenging environments, following isolation and lockout procedures precisely, working to method statements without deviation, fault-finding and reactive maintenance skills.

Progression pathway: Exposure to specialized systems beneficial for career development. However, industrial environments often require existing experience before accepting mates/improvers. Entry challenging without prior industrial exposure. Benefits: Stable employment often with direct contracts, exposure to complex systems, potential for specialist skill development. Challenges: Higher safety expectations from day one, less tolerance for errors in live plant environments, may require existing experience making entry-level access difficult.

Common rejection reasons: Inability to follow safety procedures precisely, casual attitude toward isolation and permit systems, lack of focus in high-risk environments, previous industrial safety incidents.

Social Housing and Facilities Management

Typical employer profile: Housing associations, local authority contractors, building management companies, facilities management firms.

Mate/improver role characteristics: Reactive maintenance and repair work, testing programs (periodic inspection), social housing compliance requirements, customer service in occupied social housing, documentation-heavy for compliance audit trails, regular routes and familiar sites, less new installation, more testing and repair.

Card requirements: ECS often required for larger contractors. However, some smaller housing association contractors operate with more flexibility. DBS checks required for working in occupied social housing.

Key skills emphasis: Customer service skills working with vulnerable tenants, testing and inspection procedures, completing compliance documentation accurately, working independently on minor repairs, reactive problem-solving, regular attendance and reliability for scheduled maintenance programs.

Progression pathway: Testing and inspection focus beneficial for progression toward 2391 Inspection and Testing qualification. Regular work provides stable NVQ evidence gathering environment. Benefits: Stable employment, regular hours, lower physical demands than new build, progression toward testing specialization. Challenges: Less exposure to new installation techniques, paperwork-heavy administrative burden, may require DBS clearance.

Common rejection reasons: Poor customer service with vulnerable tenants, inaccurate compliance documentation creating audit failures, unreliability affecting scheduled maintenance programs.

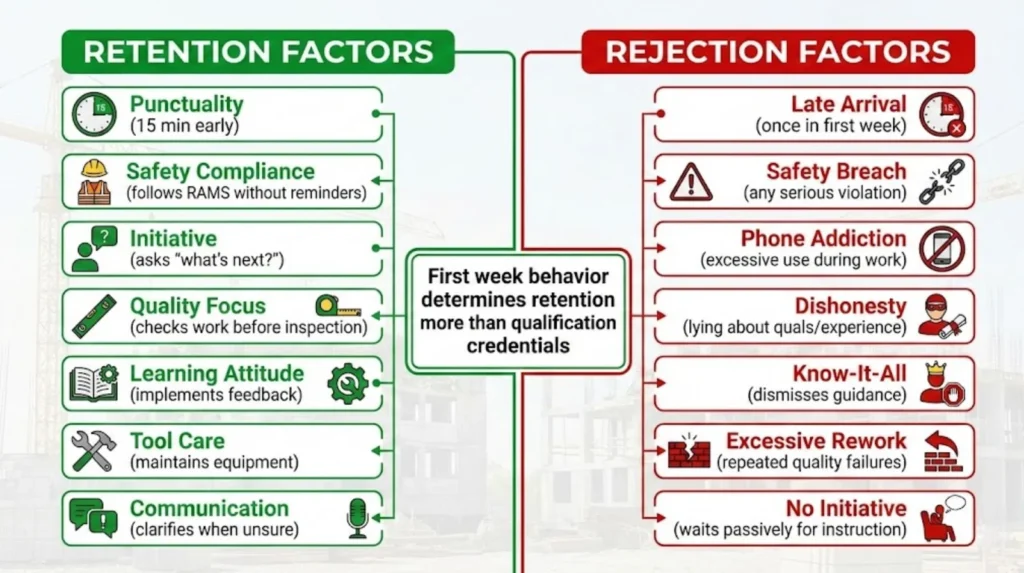

Common Rejection Reasons

Understanding why candidates fail to secure or retain mate and improver positions prevents repeatable errors.

For Mates:

Poor attendance and punctuality: Single late arrival in first week often results in immediate dismissal or not being invited back. Pattern of Monday absences or Friday early departures signals unreliability. Vague illness excuses without advance notice. Consistent late arrivals of 5 to 10 minutes despite warnings.

Lazy or low-effort behavior: Standing idle waiting to be told every task rather than asking “what’s next?” Excessive phone use during working hours. Slow, reluctant movement when asked to fetch materials or tools. Treating supportive tasks as beneath them. Complaining about physical work or site conditions.

Basic tool incompetence: Inability to use common hand tools (screwdrivers, spanners, pliers) correctly. Damaging materials through careless handling or incorrect tool use. Not knowing tool names when asked to fetch items. Leaving tools disorganized or failing to return borrowed equipment.

Safety non-compliance: Not wearing PPE without constant reminders. Ignoring safety barriers or working in prohibited areas. Casual attitude toward height work or electrical hazards. Failure to follow RAMS or site-specific protocols after induction.

Poor communication: Not asking when instructions unclear, then making errors. Inability to confirm understanding or repeat back instructions. Excessive talking distracting others from work. Inappropriate language or behavior on client sites.

Lack of initiative: Never anticipating needs or preparing materials proactively. Requiring explicit instruction for obvious next steps. Not organizing work area or preparing for upcoming tasks. Waiting passively rather than identifying supportive tasks independently.

For Improvers:

Inability to work with limited supervision: Requiring step-by-step instruction for basic tasks after initial demonstration. Unable to complete straightforward installations (containment runs, socket circuits) independently with only periodic checks. Constantly asking qualified electrician for guidance on routine procedures. Functionally operating as mate despite holding qualifications and receiving improver wages.

Poor quality requiring excessive rework: Installations failing quality inspection requiring reinstallation. Measurements and positioning inaccurate causing coordination problems with other trades. Terminations loose, poorly made, or unsafe requiring correction. Damage to building fabric or materials through careless work.

Slow productivity hindering team output: Work pace significantly below expectations for experience level. Taking excessive time on basic tasks. Not improving speed despite repetition and experience. Creating bottlenecks for team workflow.

“Know-it-all” attitude despite limited competence: Dismissing experienced electrician’s guidance. Arguing about procedures or techniques. Claiming superior knowledge from recent training despite minimal site experience. Resistance to feedback or correction.

Poor drawing literacy: Inability to read construction drawings and locate work accurately. Repeated errors positioning installations due to misunderstanding plans. Needing qualified electrician to interpret every drawing rather than working from plans independently for straightforward installations.

Failure to recognize competence limits: Attempting tasks beyond capability without seeking guidance. Overconfidence leading to errors or safety issues. Not admitting knowledge gaps, then making costly mistakes.

For Both Roles:

Safety breaches: Any serious safety violation typically results in immediate site removal and employment termination. Cannot be remedied through additional training if fundamental judgment lacking. Includes: working on live circuits without authorization, ignoring isolation procedures, unsafe height work, creating hazards for others.

Dishonesty: Lying about qualifications, experience, or previous employment. Falsifying timesheets or documentation. Stealing materials or tools. Damage to trust impossible to repair.

Interpersonal conflicts: Aggressive or threatening behavior toward colleagues. Sexual harassment or discrimination. Persistent conflicts with site management or other trades. Creating toxic work environment.

Substance issues: Appearing under influence of alcohol or drugs. Attendance problems related to substance use. Safety risks from impaired judgment.

Persistent non-improvement: Repeating same errors despite multiple corrections and warnings. Failure to implement feedback over extended period. Lack of any observable skill development after reasonable training period (typically 3 to 6 months probation).

Myths vs Reality

Common assumptions about mate and improver employability require evidence-based correction.

Myth: “Level 3 diploma makes you an improver automatically”

Reality: Diploma signals theoretical knowledge and workshop practical capability. Improver status requires demonstrated competence working with limited supervision on actual sites, references from qualified electricians confirming capability, behavioral reliability proven over time, appropriate ECS Trainee card for site access.

Employers distinguish between qualifications (what you’ve learned) and competence (what you can do reliably under working conditions). Diploma-holder without site experience viewed as “mate with a book” until proving practical capability.

Verdict: False. Diploma necessary but insufficient. Improver status requires demonstrated competence evidence, not just certificates.

Myth: “Mates don’t need any site experience”

Reality: Employers prefer candidates with basic construction site exposure even for mate roles. Previous work as general laborer, experience in other construction trades, or informal site exposure demonstrates: understanding of construction culture and behavior, safety awareness in working environments, physical capability for manual work, reliability in demanding conditions.

Candidate with 3 to 6 months general construction laborer experience plus minimal electrical knowledge often preferred over electrical student with zero site exposure. Known behavioral quantity reduces risk.

Verdict: False. While not absolutely required, basic site experience significantly improves mate employability versus complete construction site inexperience.

Myth: “Improvers are basically electricians”

Reality: Substantial competence gap exists between improvers and qualified electricians. Improvers cannot: work unsupervised or completely autonomously, sign off electrical installations or issue certificates, work on live systems without direct qualified oversight, make final compliance decisions about BS 7671 requirements, legally advertise services as electrician.

Improvers work under qualified supervision building toward full qualification through NVQ Level 3 and AM2 assessment. Significant learning and competence development remains before achieving electrician status.

Verdict: False. Improvers are progressing learners requiring supervision, not near-equivalent to qualified electricians despite possessing theoretical knowledge.

Myth: “Cards matter more than behavior”

Reality: ECS cards enable site access (permission gateway) but don’t guarantee employment or retention. Card proves minimum safety awareness and qualification enrollment. Behavior determines whether candidate: gets hired after card screening (interview performance, references, attitude assessment), retains employment past probationary period (punctuality, reliability, quality, safety compliance), progresses in role (learning attitude, initiative, competence development).

Verdict: Partially true. Cards essential for site access filtering but behavior determines actual employment outcomes. Both required, behavior more decisive for retention.

Myth: “Employers want speed above everything”

Reality: Employers prioritize quality and safety over speed. Rework costs more than initial slower careful work. Fast installation requiring complete reinstallation due to poor quality or safety issues costs significantly more in: materials replacement, additional labor time, project delays, damage to employer reputation.

Employers tolerate developing speed with experience if quality remains consistent. Cannot tolerate persistent quality failures or safety shortcuts regardless of speed.

Verdict: False. Quality and safety precede speed. Employers value “right first time” over “fast but wrong.”

Myth: “One definition applies everywhere”

Reality: Mate and improver terminology varies by: employer size and structure, sector (domestic vs commercial vs industrial), region (London vs regional practices), contractor culture and supervision capacity.

Mate on large infrastructure project may have more responsibility than improver at small domestic firm. Definitions reflect supervision capacity and role expectations rather than universal standards.

Verdict: True. Definitions vary substantially. Focus on supervision requirements and task expectations rather than job titles.

Myth: “Partial qualifications guarantee interviews”

Reality: Qualifications help filter candidates for interview selection but don’t guarantee employment. Employers screen: behavioral signals from application (spelling, grammar, professionalism), references from previous employers or trainers, relevant experience even if non-electrical, practical assessment during interview or trial period.

Candidate with Level 2 diploma, poor references, and unprofessional application likely rejected despite qualifications. Candidate with minimal qualifications, strong references, professional presentation progresses further.

Verdict: Partially false. Qualifications improve interview likelihood but don’t guarantee employment. Behavioral and competence signals often more decisive.

Myth: “You can’t be a mate if you’re over 30”

Reality: Older career changers (ages 30 to 50+) often preferred for mate and improver roles due to: maturity and life experience, reliability and work ethic, professional behavior with clients and colleagues, lower risk of attitude problems common in younger workers.

Employers sometimes specifically seek adult career changers for these behavioral strengths despite needing training in technical electrical skills. Age becomes advantage if accompanied by professional maturity.

Verdict: False. Adult career changers often advantaged for behavioral reliability despite technical learning curve.

Myth: “Knowing the regulations is most important for mates”

Reality: For mates, behavioral reliability and practical capability matter more than BS 7671 knowledge. Employers prioritize: punctuality and attendance, following instructions precisely, physical capability for manual work, safety awareness and PPE compliance, initiative in supportive tasks.

Mate who knows 18th Edition but arrives late and requires constant reminding gets dismissed. Mate who knows minimal theory but reliably supports qualified electrician gets retained and developed.

For improvers, regulatory knowledge becomes more important but still secondary to behavioral reliability and practical competence.

Verdict: False for mates. Behavioral factors outweigh technical knowledge. Partially true for improvers where both matter but behavior still foundational.

Myth: “Agencies enforce universal standards”

Reality: Agencies adapt job descriptions to client demands and use filtering shortcuts. Same job title across different agencies may reflect different employer expectations. Agencies prioritize: quickly filling positions over precise role definition, filtering large applicant volumes using simple criteria (card type, transport, tools), client-specific requirements varying widely.

Job seekers should clarify actual role expectations directly with employer when possible rather than assuming agency description reflects universal standard.

Verdict: True. Agency descriptions reflect individual client demands rather than consistent industry-wide standards for mates and improvers.

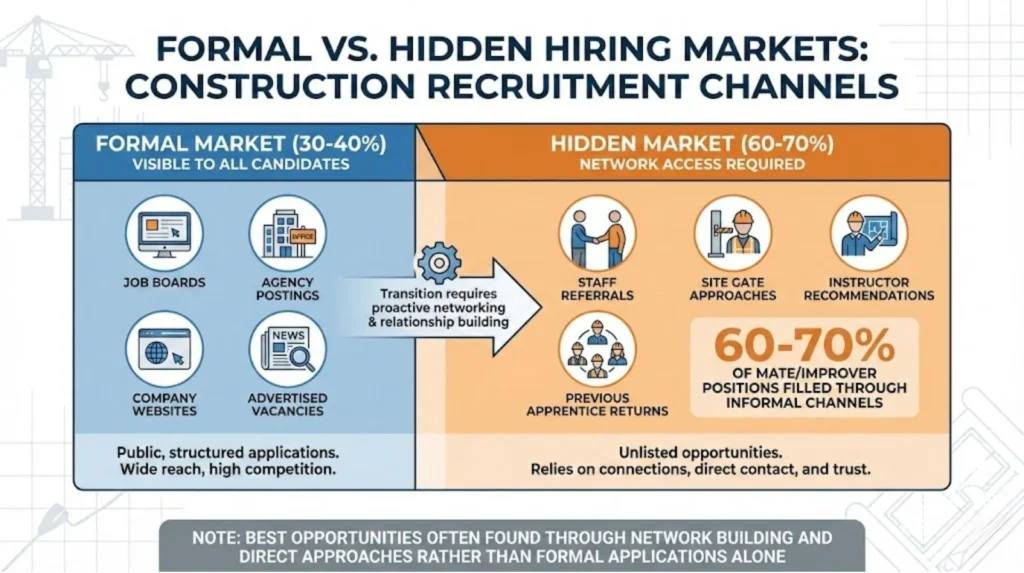

The Hidden Market: Network-Based Hiring

Substantial proportion of mate and improver positions never advertise through formal channels, creating invisible opportunity market favoring networked candidates.

How Hidden Market Operates

Informal referrals: Qualified electricians recommend family members, friends, acquaintances to employers. Existing staff vouch for candidate’s reliability based on personal knowledge. Contractors trust worker recommendations from reliable employees reducing hiring risk.

Site gate approaches: Candidates visiting active construction sites introducing themselves to site managers or foremen. Demonstrating initiative and confidence through direct approach. Leaving contact details for future opportunities when positions become available.

Training provider connections: College instructors receiving employer inquiries about available graduates. Placement coordinators at training centers maintaining contractor relationships. Instructors recommending specific students based on observed classroom reliability and capability.

Previous apprentice returns: Workers who completed apprenticeships or training with contractor returning after working elsewhere. Established relationship and known performance reducing hiring uncertainty. Contractor preference for workers familiar with company procedures and culture.

Trade forum recommendations: Experienced electricians suggesting candidates they’ve worked with previously. Online and in-person trade community referrals. Reputation-based hiring within local electrical trade networks.

Why Hidden Market Exists

Risk reduction: Personal referrals carry implicit guarantee of reliability from trusted source. Known quantity versus unknown applicant from job board reduces hiring uncertainty. References from people contractor trusts outweigh formal credentials from strangers.

Time efficiency: Screening hundreds of formal applications requires substantial time investment. Hiring referred candidate bypasses extensive screening process. Immediate availability of recommended workers versus delayed formal recruitment.

Cultural fit: Referred candidates more likely to match contractor’s working style and expectations. Existing relationship through referrer creates smoother integration. Reduced risk of interpersonal conflicts or cultural mismatches.

Quality signal: Worker willing to stake reputation on recommendation suggests high confidence in candidate. Referrer’s ongoing relationship with contractor creates accountability ensuring quality referrals.

Accessing Hidden Market

Build construction networks: Attend trade events, supplier open days, industry meetups. Volunteer for electrical charity work or community projects connecting with qualified electricians. Join trade associations or local electrical groups.

Leverage training connections: Maintain contact with college instructors who hear about opportunities. Request instructors recommend you to employer inquiries. Demonstrate exceptional reliability and capability during training to become preferred referral.

Direct site approaches: Visit active construction sites during lunch breaks or end of day. Introduce yourself professionally to site managers explaining your situation (mate seeking experience, improver building NVQ evidence). Leave contact details and follow up if encouraged. Dress appropriately (clean work clothes, safety boots visible) demonstrating seriousness.

Temporary agency placements: Accept short-term agency assignments even if not ideal. Demonstrate excellent performance creating references and potential direct hire opportunities. Use agency placements to build site experience and network connections.

Maintain relationships: Stay in contact with employers even after brief placements end. Update former supervisors on qualification progress and availability. Strong impression during short placement can lead to callback when positions open.

Professional online presence: LinkedIn profile highlighting electrical training, site experience, availability, location. Join electrical trade groups on social media platforms. Engage constructively in discussions demonstrating knowledge and professional attitude.

Realistic Assessment

Hidden market access requires: 3 to 6 months consistent effort building connections and demonstrating reliability, willingness to accept initial lower-status work (general laborer, basic mate tasks) to prove capability, professional behavior creating positive reputation enabling referrals, geographic flexibility potentially traveling to opportunities beyond immediate local area.

Not guaranteed or immediate solution. Complements formal job applications rather than replacing them. However, understanding hidden market existence explains why some qualified candidates struggle finding employment despite credentials while others with minimal qualifications secure positions through network access.

For information about formal training credentials employers look for, see our Level 2 and Level 3 electrical diplomas covering theoretical and workshop practical preparation for mate and improver roles alongside NVQ progression pathways.

Practical Assessment Framework

Evaluating employability readiness before investing time in unsuccessful applications or accepting positions misaligned with capability.

Self-Assessment: Am I Mate-Ready?

Behavioral readiness:

Can I consistently arrive 15 minutes early for 7am or 7:30am starts every day? Do I have reliable transport independent of others or public transport delays? Can I maintain punctuality and attendance over 3 to 6 month probationary period without absences? Am I physically capable of sustained manual work (8 to 9 hours daily) including lifting 20kg+ repeatedly? Can I follow instructions precisely without requiring repetition? Am I comfortable performing unglamorous tasks (cleaning, organizing, material movement) without complaints? Can I maintain focus and avoid phone distractions during working hours?

Practical capability:

Do I know basic hand tool names and purposes (screwdrivers, spanners, pliers, wire strippers, spirit level)? Can I use these tools correctly without damaging materials or injuring myself? Am I comfortable working at heights on ladders and scaffolding following safety procedures? Can I work in confined spaces (lofts, underfloor, tight rooms) without claustrophobia or safety concerns?

Regarding practical capability requirements for electrical work, assess honestly whether any physical limitations (vision, dexterity, mobility) would prevent safe task performance before pursuing mate roles.

Site access:

Do I have or can I obtain ECS Electrical Labourer card or CSCS equivalent? Have I completed basic health and safety awareness training? Do I have appropriate PPE (hard hat, hi-vis, safety boots, gloves) or resources to purchase immediately?

If answering “no” to multiple questions: Mate employment unlikely until addressing gaps. Focus on developing behavioral reliability, obtaining basic site safety credentials, acquiring PPE, improving physical capability if needed.

Self-Assessment: Am I Improver-Ready?

All mate requirements plus:

Technical capability:

Have I completed Level 2/3 electrical diplomas or equivalent training? Can I read basic construction drawings and locate work from floor plans? Do I understand BS 7671 requirements for installations I’d be performing (socket circuits, lighting, containment)? Can I perform basic installations (mounting accessories, terminating cables, installing containment) to acceptable quality without constant supervision? Do I know when to seek guidance versus proceeding independently?

Practical experience:

Have I accumulated any site experience (even as mate or general laborer) demonstrating construction site behavior? Can I provide references from qualified electricians, instructors, or supervisors confirming capability and reliability? Have I demonstrated ability to work with task-based supervision rather than requiring constant oversight?

Professional commitment:

Do I have personal tool kit including battery-powered tools, hand tools, testing equipment appropriate for improver level (investment £500 to £2,000)? Am I enrolled in or planning NVQ Level 3 progression with identified assessor? Do I hold ECS Trainee card demonstrating progression toward qualification?

If answering “no” to multiple technical or experience questions: Improver employment premature. Consider mate positions first to build site experience and competence evidence, or accept that diploma-only credentials require substantial site experience before improver-level employment realistic.

Employer Perspective Check

When evaluating job opportunities, assess employer expectations realistically:

Red flags suggesting problematic employment:

“Must be able to work completely alone” for improver positions (indicates inadequate supervision capacity). “Immediate start” repeatedly posted same position (suggests high turnover, problematic site culture). Vague or contradictory job descriptions (employer unclear on actual role requirements). Extremely low wages even for region (suggests quality employer unlikely). Unwillingness to provide details about supervision arrangements during interview (supervision may be inadequate or absent).

Green flags suggesting quality opportunity:

Clear supervision structure explained during interview (who will supervise, how often, what support available). Realistic expectations matching role level (not expecting autonomous work from improver). Mention of training or NVQ support opportunities. Professional interview process assessing capability appropriately. Competitive wages for role and region. Willingness to discuss career progression pathways.

Trial Periods and Probation

Most mate and improver positions include probationary period (typically 2 to 12 weeks) where employer assesses fit. Understand this works both directions:

Employer assesses: Behavioral reliability (punctuality, attendance, attitude), safety compliance without constant reminders, quality and capability appropriate to role, cultural fit with team and site requirements, potential for development and progression.

Candidate should assess: Adequate supervision and training provided, reasonable expectations matching capability, professional treatment and working conditions, payment reliability and fairness, genuine progression opportunities versus dead-end position.

Be prepared to exit poor-fit situations during probation rather than persisting in problematic employment damaging career development or safety.

Call 0330 822 5337 to discuss realistic pathways into electrical work as mate or improver. We’ll provide honest assessment of whether your current qualifications and experience align with employer expectations, explain competence requirements beyond certificate credentials preventing costly assumptions about immediate employability, clarify supervision differences between mate and improver roles helping you target appropriate positions, recommend whether additional site experience or training needed before applications, connect you with placement support if you’re NVQ-ready needing site access. No false promises about guaranteed employment. No dismissal of genuine preparation gaps. Just evidence-based guidance helping you understand what employers actually look for versus what training marketing suggests, reducing application frustration and increasing employment success probability when you’re genuinely ready.

References

- Health and Safety Executive (HSE) – Electricity at Work Regulations 1989 – https://www.hse.gov.uk/electricity/index.htm

- Health and Safety Executive (HSE) – Working Safely with Electricity – https://www.hse.gov.uk/electricity/withequip.htm

- Electrotechnical Certification Scheme (ECS) – Card Types and Requirements – https://www.ecscard.org.uk/card-types

- ECS – Electrical Labourer Card – https://www.ecscard.org.uk/card-types/Electrotechnical/Electrical-Labourer

- Joint Industry Board (JIB) – Grading Definitions and National Working Rules – https://www.jib.org.uk/

- Joint Industry Board (JIB) – PMES Scheme – https://www.jib-pmes.org.uk/

- Electrical Contractors’ Association (ECA) – Apprenticeships and Skills – https://www.eca.co.uk/member-support/education-skills/apprenticeships

- National Careers Service – Electrician Job Profile – https://nationalcareers.service.gov.uk/job-profiles/electrician

- Construction Skills Certification Scheme (CSCS) – Card Types – https://www.cscs.uk.com/

- City & Guilds – 2365 Electrical Installation Diplomas – https://www.cityandguilds.com/

- City & Guilds – 2357/5357 NVQ Electrical Installation – https://www.cityandguilds.com/

- Reed – Electrical Mate Jobs – https://www.reed.co.uk/jobs/electrical-mate-jobs

- CV-Library – Electrical Improver Jobs – https://www.cv-library.co.uk/electrical-improver-jobs

- Electricians Forums – Mate vs Improver Discussions – https://www.electriciansforums.net/

- SELECT (Scotland) – Electrical Contracting Trade Body – https://www.select.org.uk/

- Scottish Joint Industry Board (SJIB) – Grading System – https://www.sjib.org.uk/

- BS 7671:2018+A2:2022 – IET Wiring Regulations – https://www.theiet.org/

- Elec Training – UK Electrician Qualification Pathway – https://elec.training/news/how-to-become-an-electrician-in-the-uk-2026/

- Elec Training – Courses Overview – https://elec.training/courses/

Note on Accuracy and Updates

Last reviewed: 31 December 2025. This page is maintained; we correct errors and refresh sources as employer practices, card requirements, qualification frameworks, and hiring patterns change. Role definitions (mate, improver, electrician) reflect functional distinctions based on supervision requirements rather than universal standards, as terminology varies across employers, regions, and sectors. Pay ranges accurate for December 2025 but vary substantially by geographic location, employer size, sector, and individual circumstances. ECS card requirements represent majority practice on commercial sites but some employers (particularly domestic) operate with different access policies. Job advert language interpretation based on recruitment pattern analysis but individual employer usage varies. Hidden market proportion estimates (60-70% informal hiring) based on industry practitioner reports and trade forum discussions rather than formal labor statistics which don’t track informal recruitment channels. Common rejection reasons drawn from placement manager experience and employer feedback rather than published termination data. Self-assessment framework provides guidance structure but individual readiness varies by personal circumstances, learning pace, and local market conditions. Next review scheduled following significant changes to: ECS card scheme requirements, JIB grading definitions, HSE supervision guidance updates, or major shifts in construction sector hiring practices affecting mate and improver access.